Our company specializes in the maintenance and upgrading of medium and low voltage electrical systems. We offer a full range of services, including:

- Maintenance of medium and low voltage switches (breakers)

- Inspections and maintenance of transformers

- Upgrading of obsolete switches with new generation models

- Expansion of electrical switchboards

- Installation of Shoreconnection switchboards for marine applications

- Relay testing on medium and low voltage systems

Our many years of experience allow us to successfully tackle even the most complex challenges, guaranteeing our customers efficient and customized solutions. We are constantly updated on the latest technologies in the sector to offer cutting-edge services.

Contact us to request a quote or more information about our services.

Here are some of our experiences

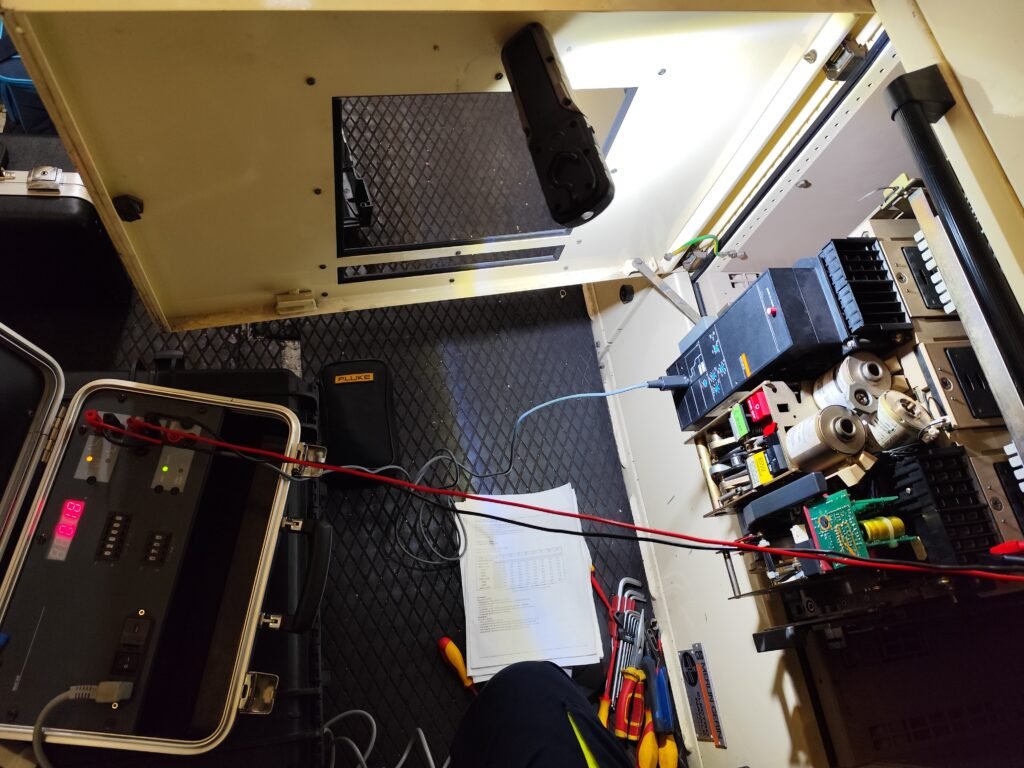

Protection Relay Testing

Protecting marine, offshore, renewable energy, and general electrical distribution systems from faults and overheating.

Protection relays are essential components of electrical distribution systems. They detect faults or short circuits, triggering circuit breakers to prevent system failures, anomalies, and fires. Regular Protection Relay Testing is crucial for maintaining system reliability and safety.

Protection relays must be tested periodically (at least every 2 years) throughout their lifespan. Modern relays offer multiple protection functions and require comprehensive testing.

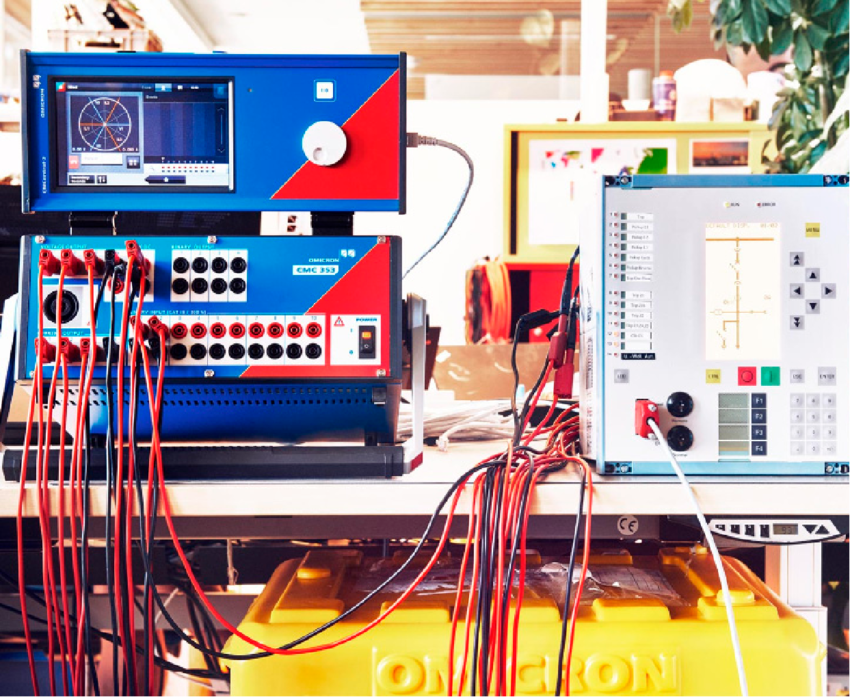

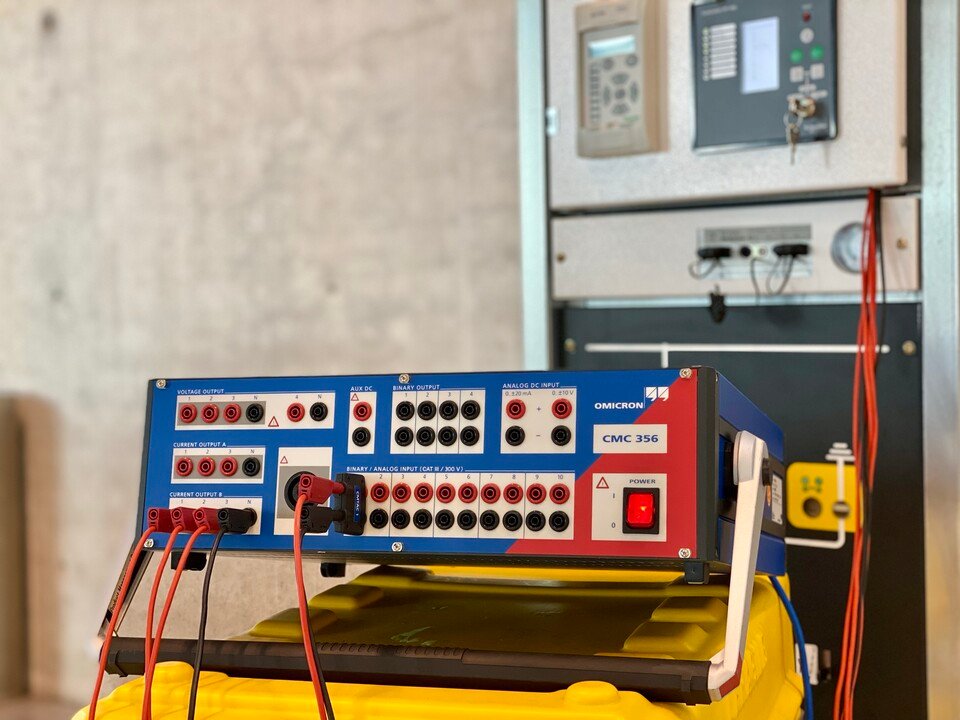

Liberty Group Team conducts rigorous testing procedures to ensure the correct operation and continuous safety of protection relays.

We guarantee proper functioning by subjecting relays to thorough tests. We pass current through the relay and compare the measured values against the manufacturer’s settings. Any discrepancies lead to recalibration, repair, or replacement.

Trip and Control Equipment Testing

Using specialized testing equipment, we assess all trip and control components within a system. We measure trip and operation times to ensure they comply with the manufacturer’s recommendations and system design. A backup of the existing configuration is taken before testing. After calibration, all settings are restored to their original values, and any modifications are documented in the test report.

Trip and Control Equipment Testing

Using specialized testing equipment, we assess all trip and control components within a system. We measure trip and operation times to ensure they comply with the manufacturer’s recommendations and system design. A backup of the existing configuration is taken before testing. After calibration, all settings are restored to their original values, and any modifications are documented in the test report.

Our Services Include:

- Testing of all electromechanical, analog, and digital relays.

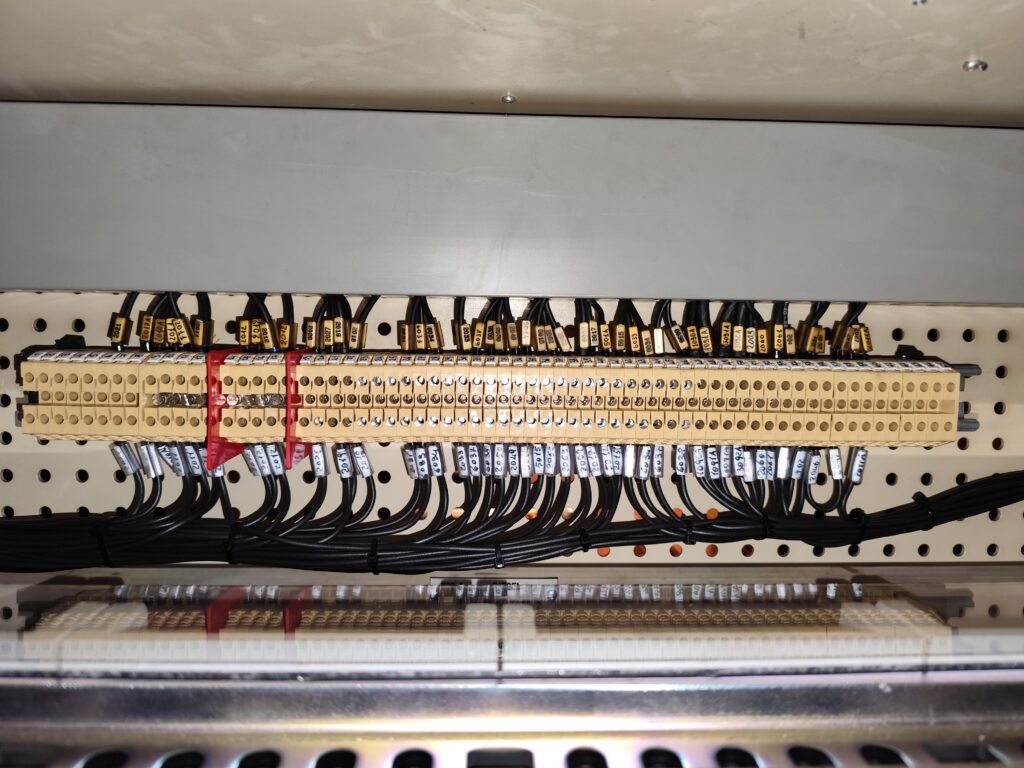

- Measurement of live CT currents, inspection of relay wiring, and tightness.

- Primary and secondary injection tests.

- Calibration of all relay types to verify operation within trip time and pickup current tolerances.

- Relay engineering, programming, setting, and scheme checking.

- Alarm testing to verify the functionality of the alarm system.

Test Reports Our detailed test reports include graphical and descriptive representations of the testing procedures. Any anomalies, repairs, or replacements are documented.

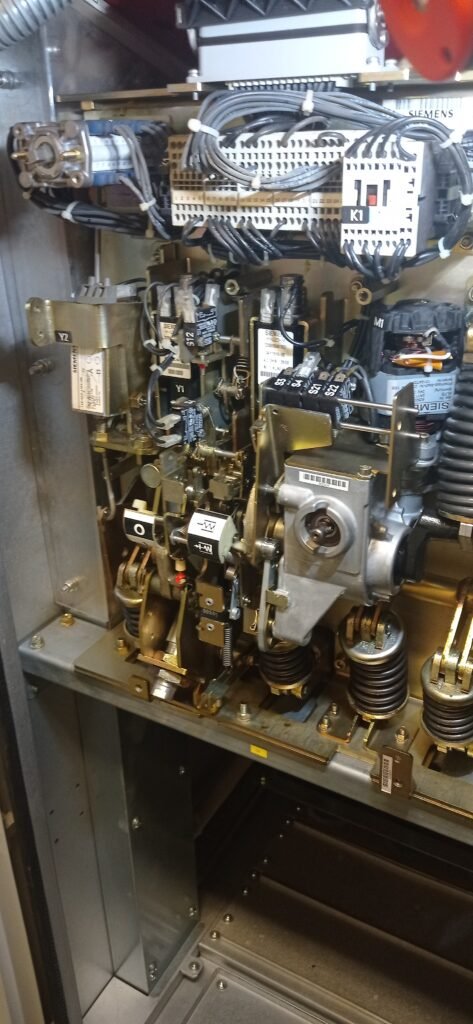

Maintenance of medium voltage circuit breakers

The maintenance of the movement and drive mechanisms of breakers is crucial. This helps prevent accidents that may occur due to poor maintenance, negligence, or lack of knowledge of the actual condition of the breaker. This reduces the likelihood of accidents, limiting the problem to chance or sudden component failure.

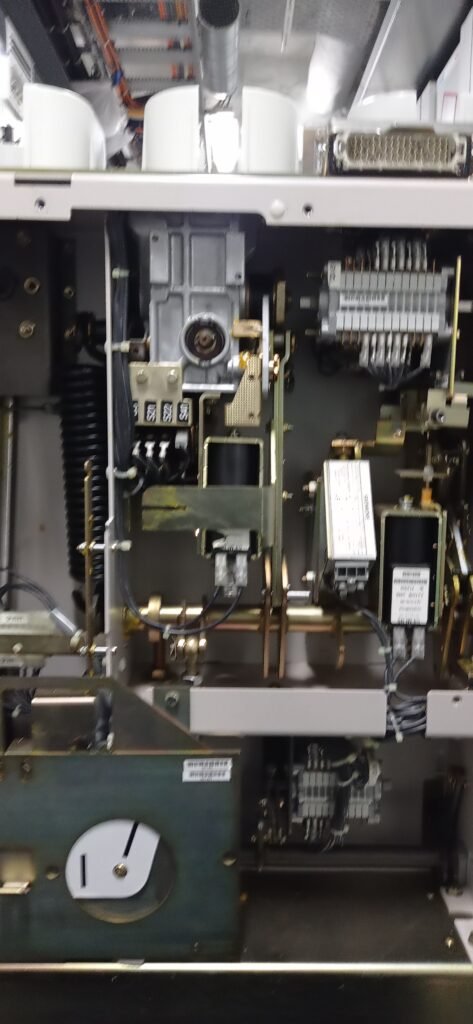

Our experience also extends to Siemens breakers, where we perform routine checks on mechanical parts, coils, the motor, bolt tightening, Sieger checks, and auxiliary moving contacts. Then we move on to the tests

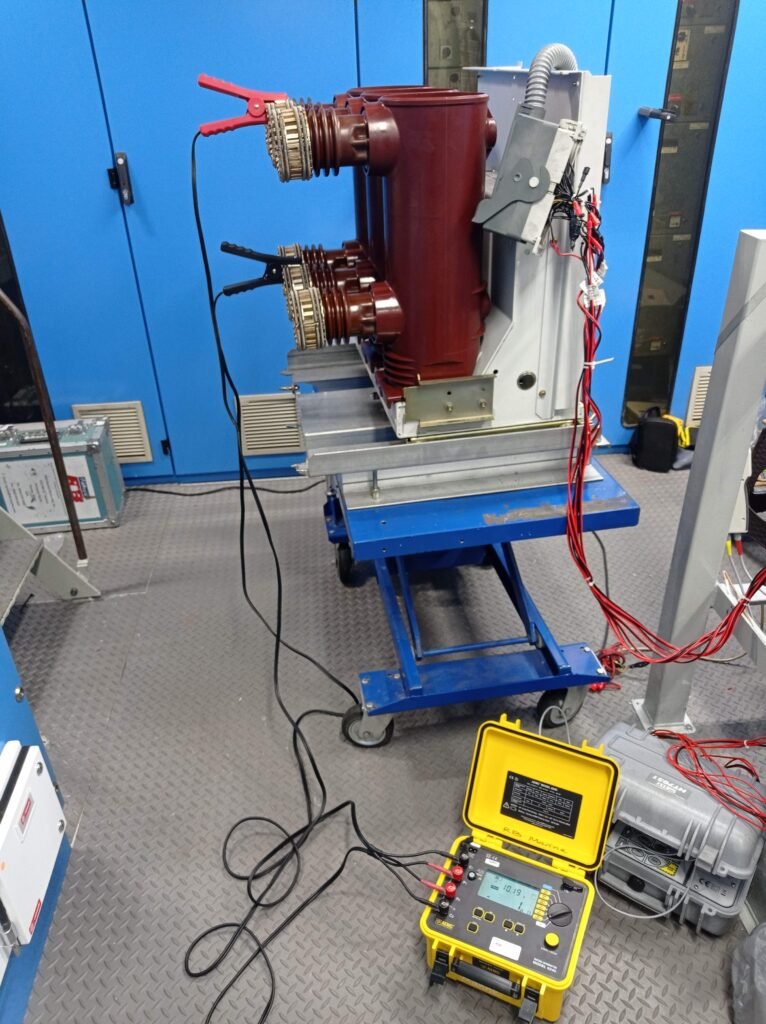

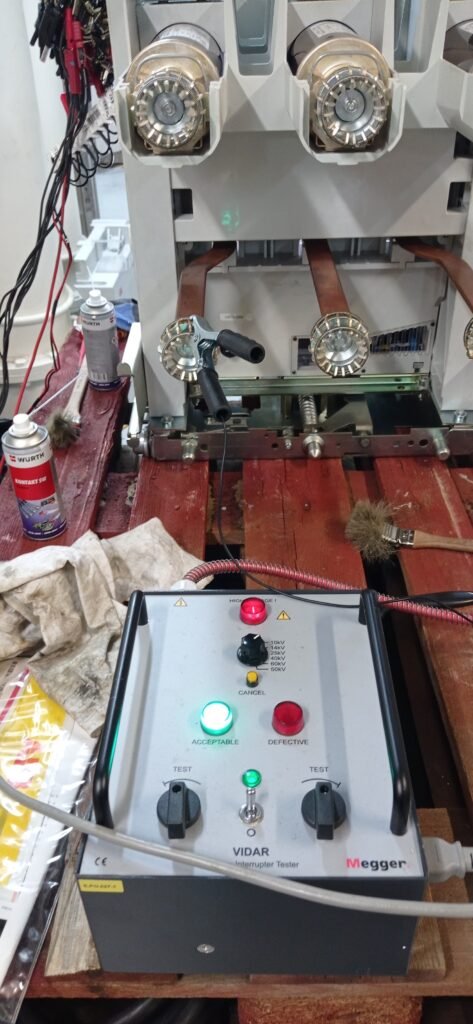

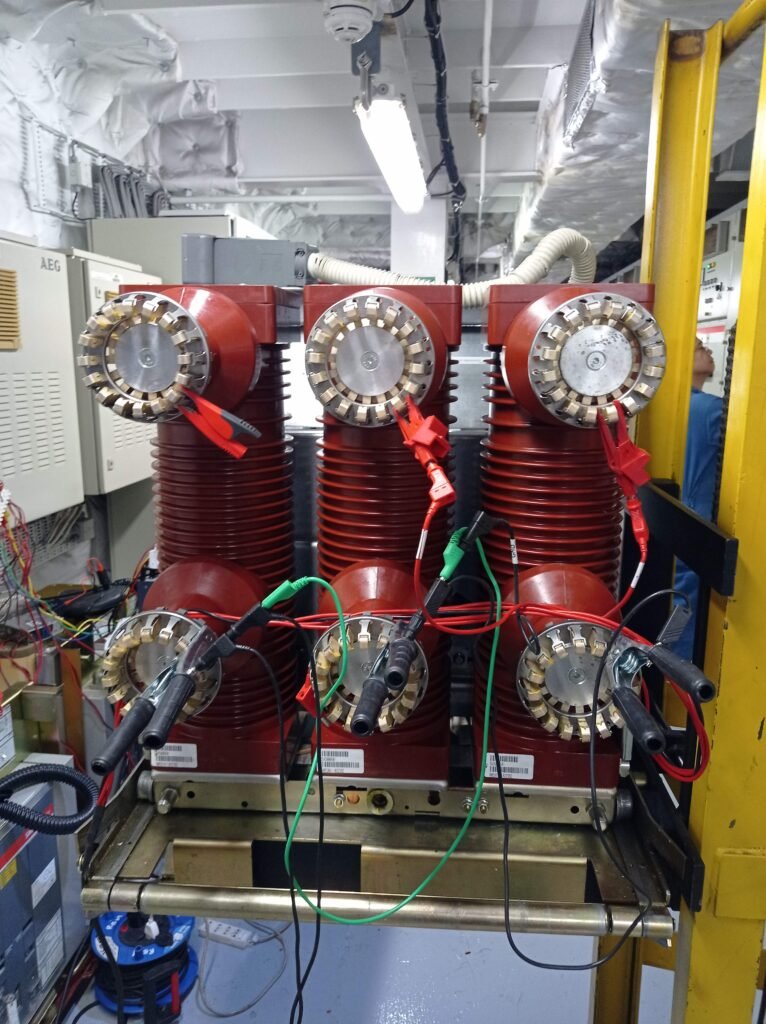

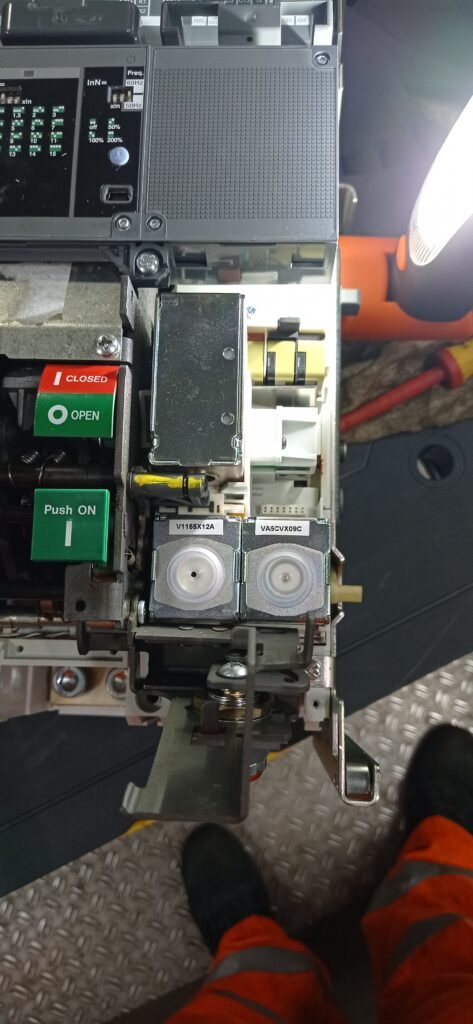

Contactor ABB VSC series

Vacuum ampoule contact test with the Vidar Instruments

SF6 Gas Test

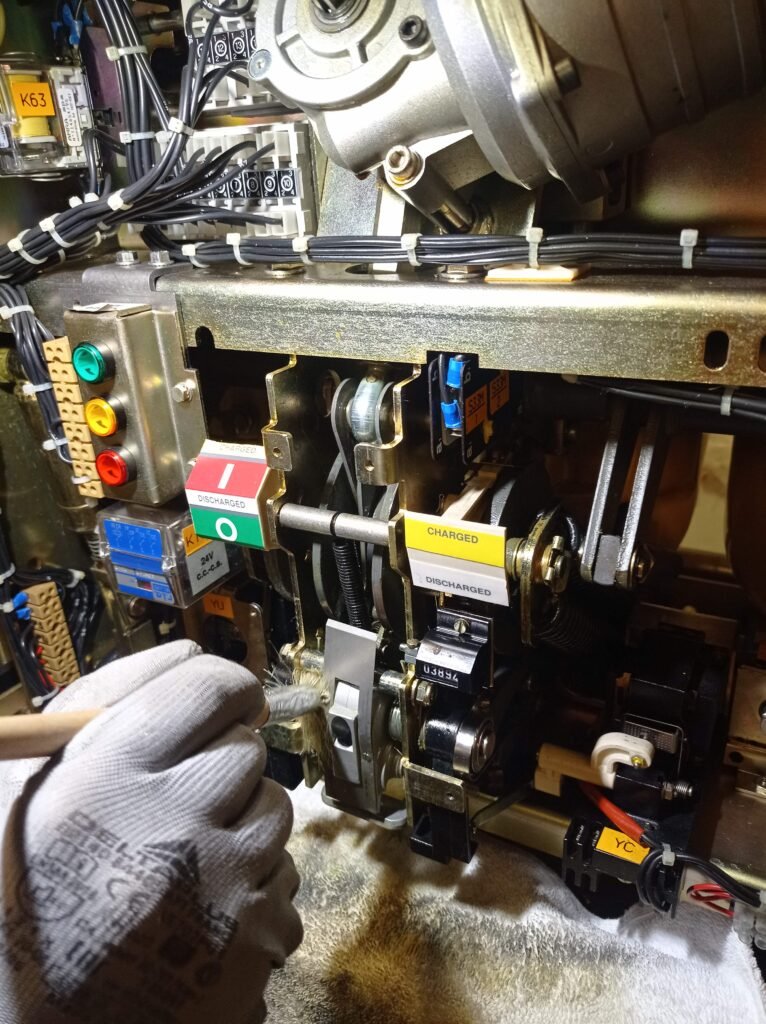

Inspection of the Main contact closure and opening mechanism

Inspection open coil

Inspection Gas SF6 Sistem

Performing Insulation and Conductivity tests is an important system for detecting the condition of the poles and electrical contacts of the Breaker. Instruments are used to detect these values and make us aware of the real conditions. For Breakers with air insulation, specific tests are then carried out to check that the contact inside the ampoule is working and effective in its insulation.

Vacuum Ampoule contact

Open contact Vacuum Ampoule

Cloesd Contact Vacuum Ampoule

Breaker HD4 internal site

Insulation Test with Open and Closed Contact

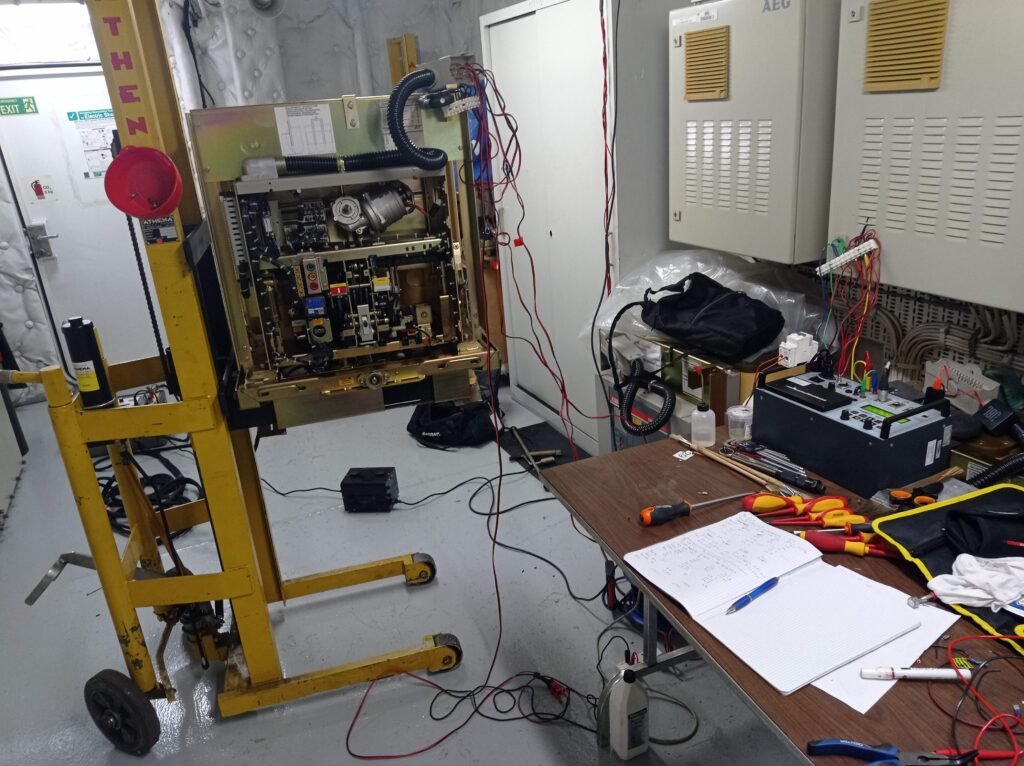

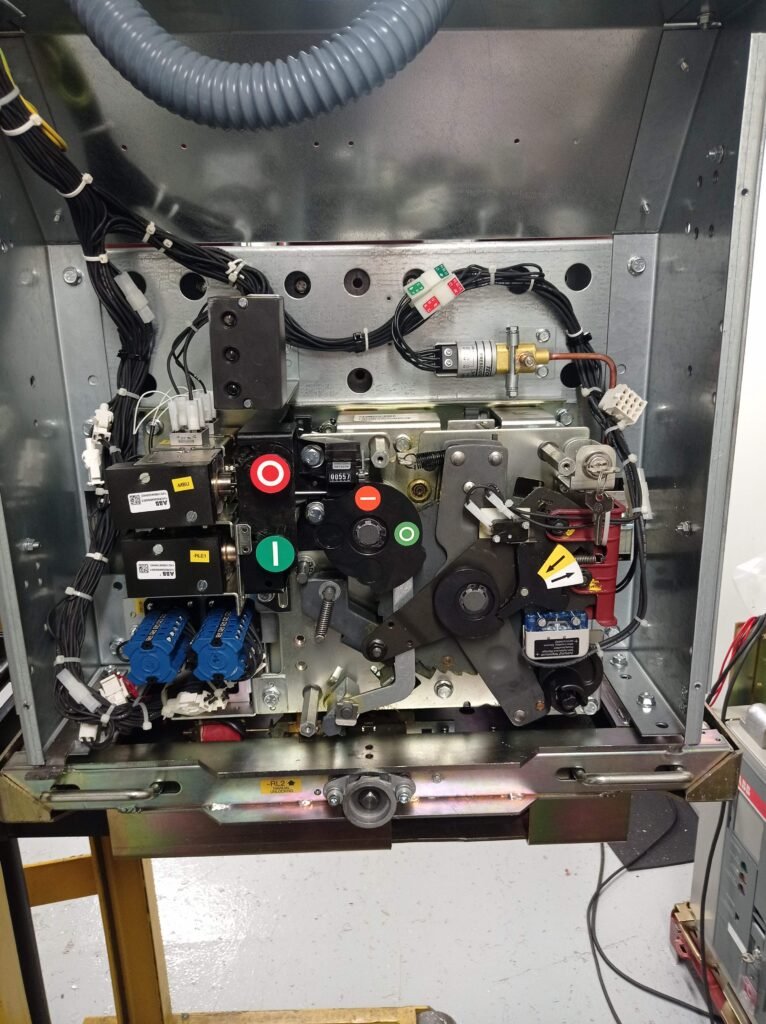

Breaker ABB Sace HA3

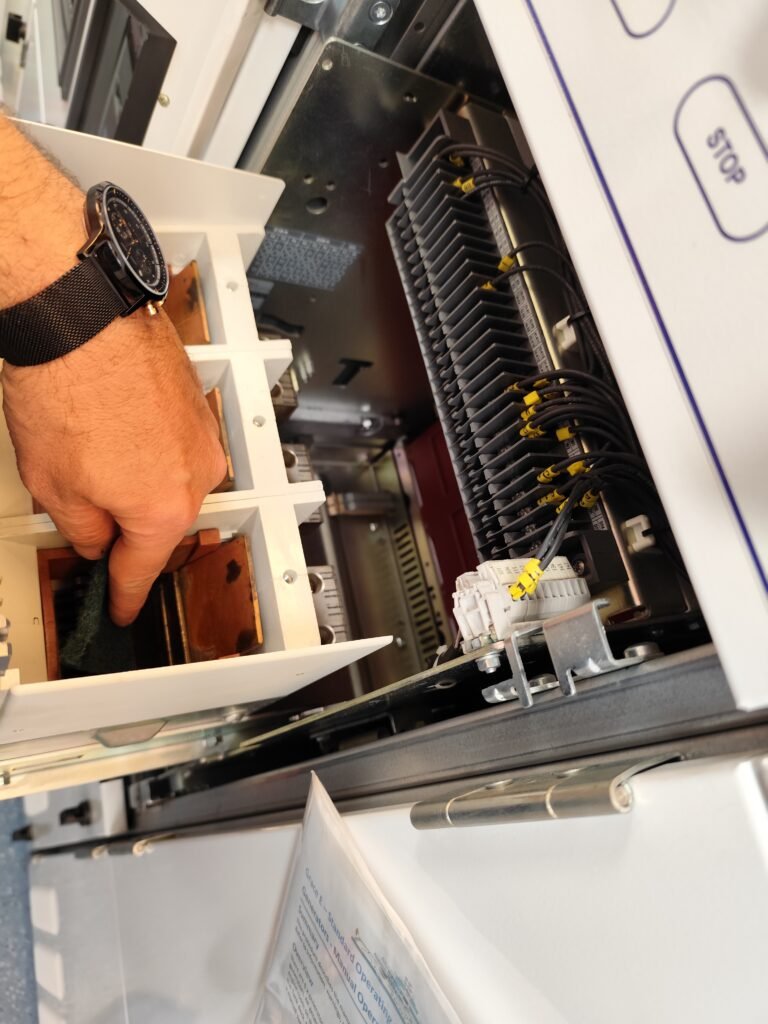

Inspection Breaker

Cleaning dust and hardened grease that hinder movements

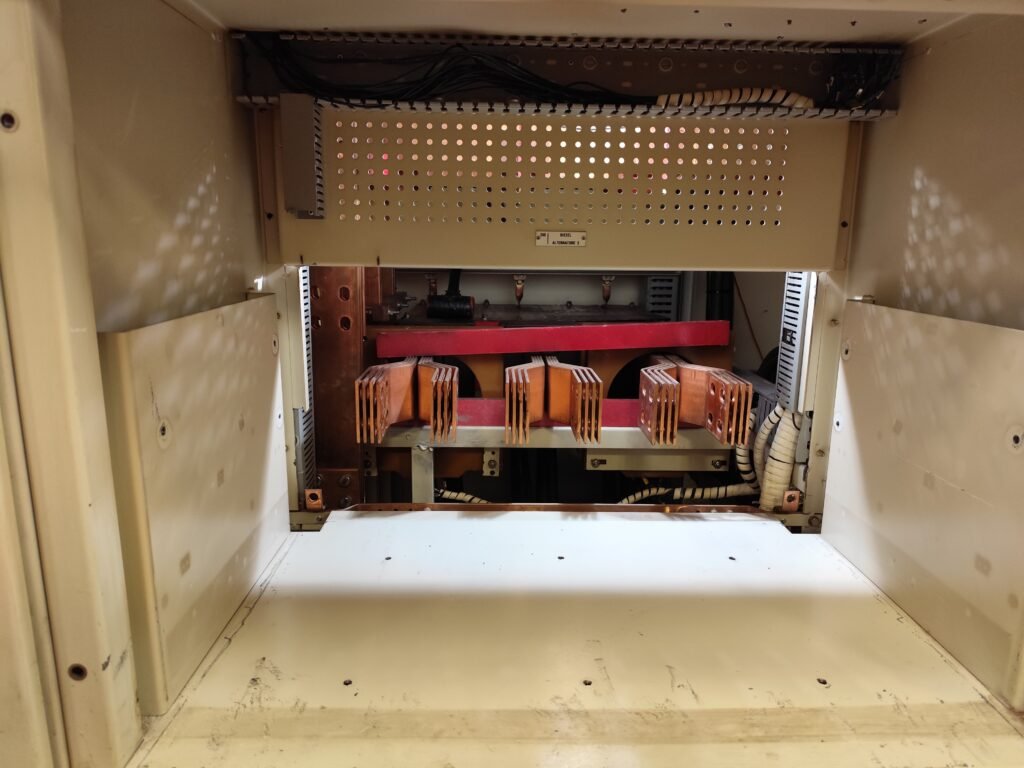

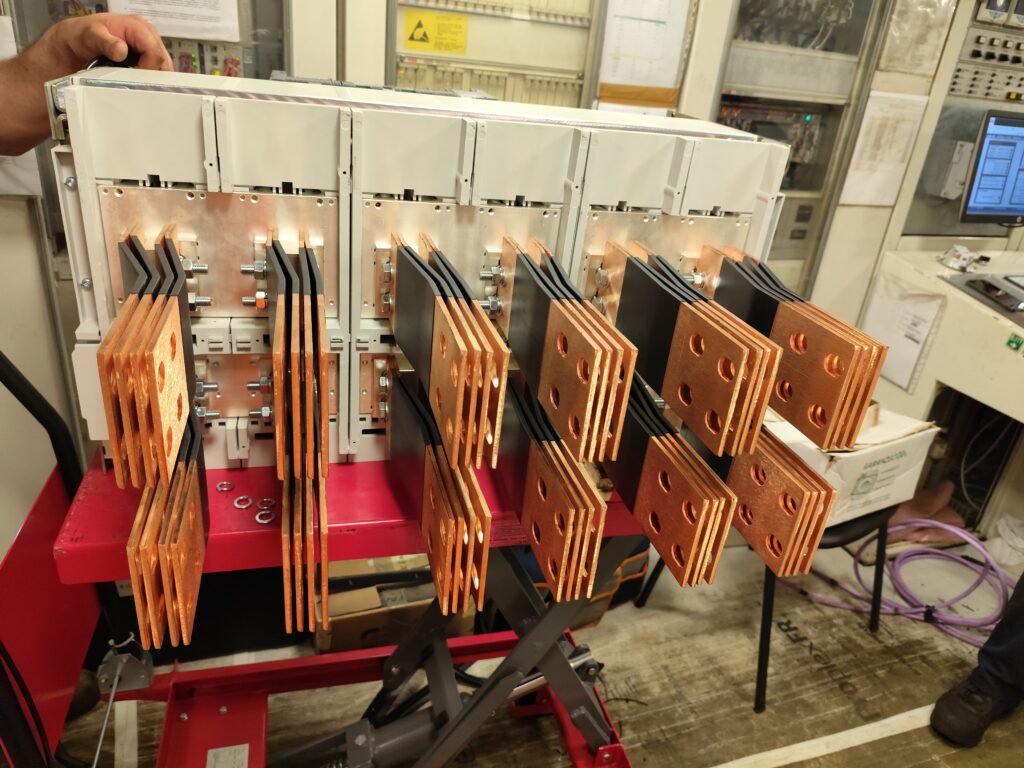

Cleaning the connection bars inside the switchboard from dust is an important operation because it eliminates any type of dust that can vary the approval values of the switchboard, and above a certain threshold, the switchboards are no longer certified for their function. Therefore, it is always recommended to keep the back of the switchboard and the copper bars clean. This becomes even more important when accidents occur that reduce conductivity due to dielectric materials deposited on the bars.

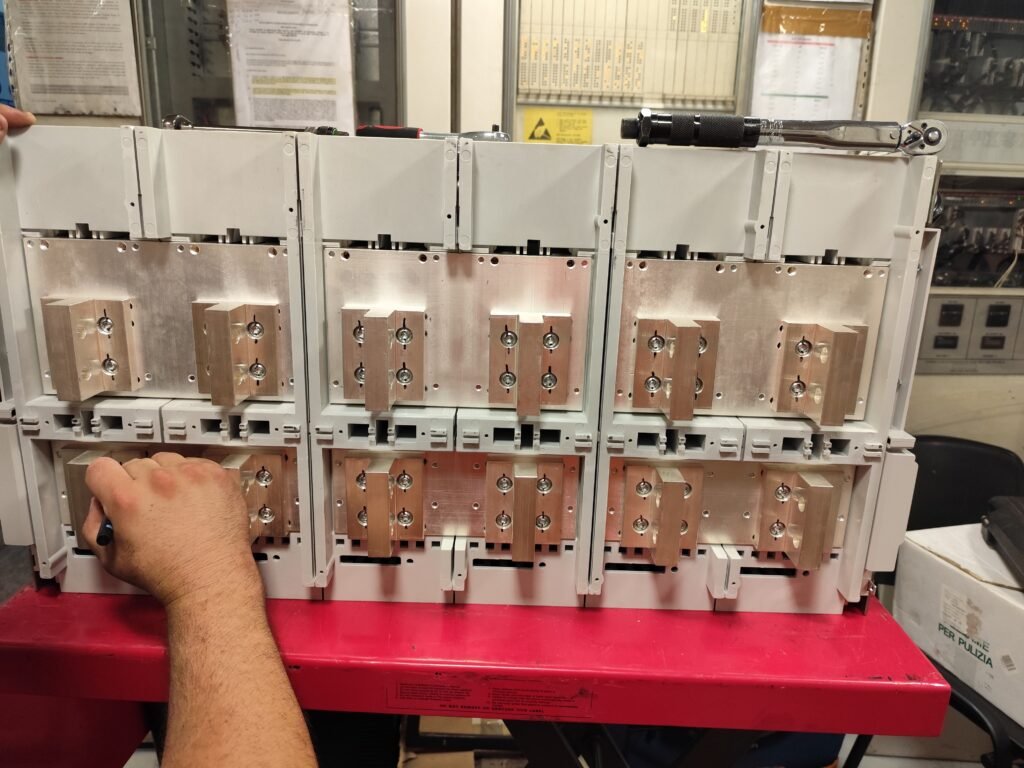

Checking the tightness of bolts is another very important operation, as it prevents possible explosions and overheating at the joints. This is a service that is often overlooked but is extremely important, especially in systems installed on ships or platforms, and particularly where there are vibration conditions over time. Maintenance consists of checking all tightening values with a torque wrench set to the correct value for each type of bolt.

When a loose bolt is identified and brought back to the correct calibration value, it must be marked just like the indicative photo below in order to understand if it is still in the correct position at the next maintenance, or if it has had any movements, this information will determine the actions to be taken.

A control system that anticipates this service can be a thermographic inspection, to find the points of interest.

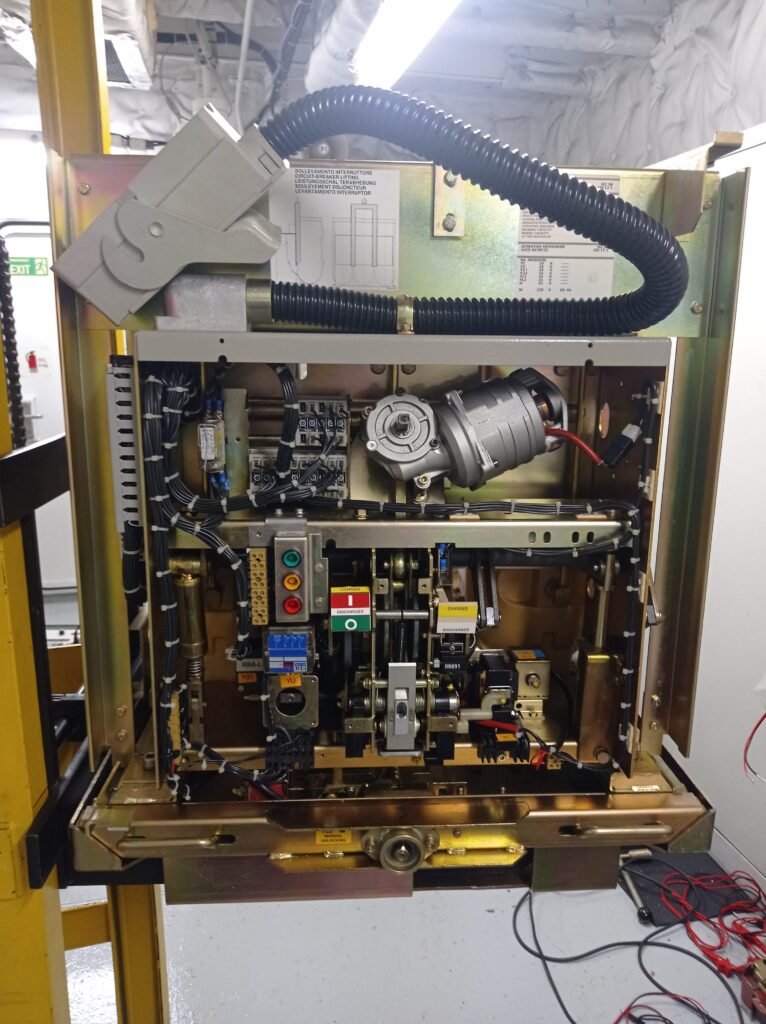

Medium Voltage Breaker ABB HD4 with Gas SF6

Test of opening and closing times, and phase shift in opening and closing

Test of opening and closing times, and phase shift in opening and closing

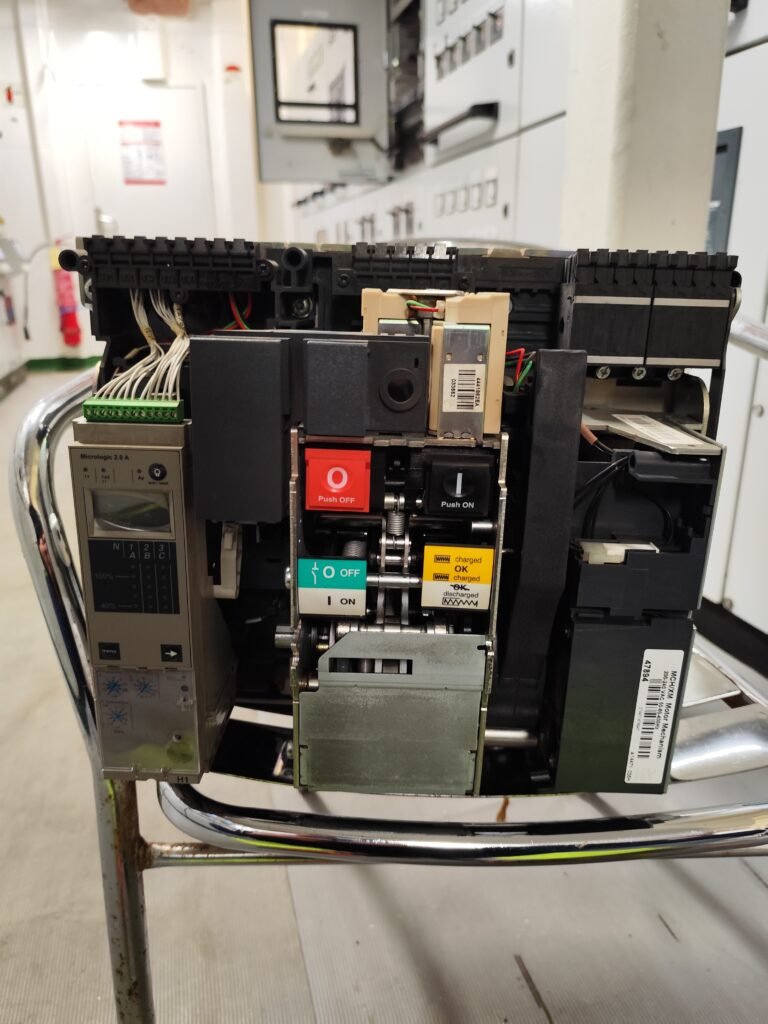

Low voltage section

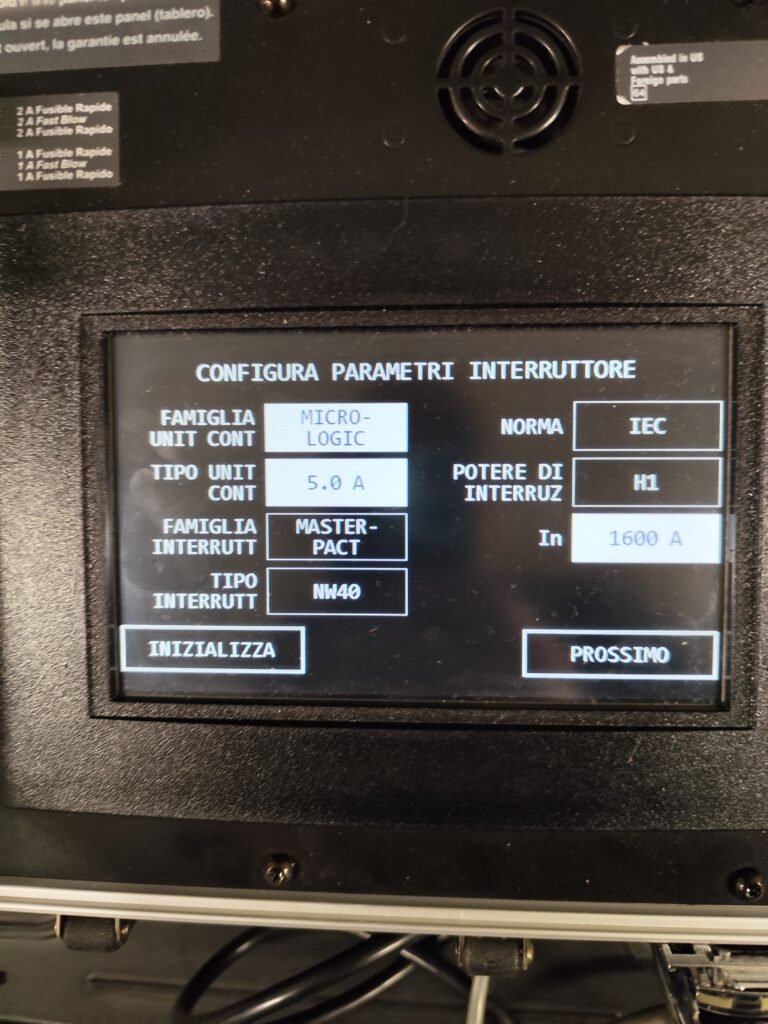

Relay Micrologic Test

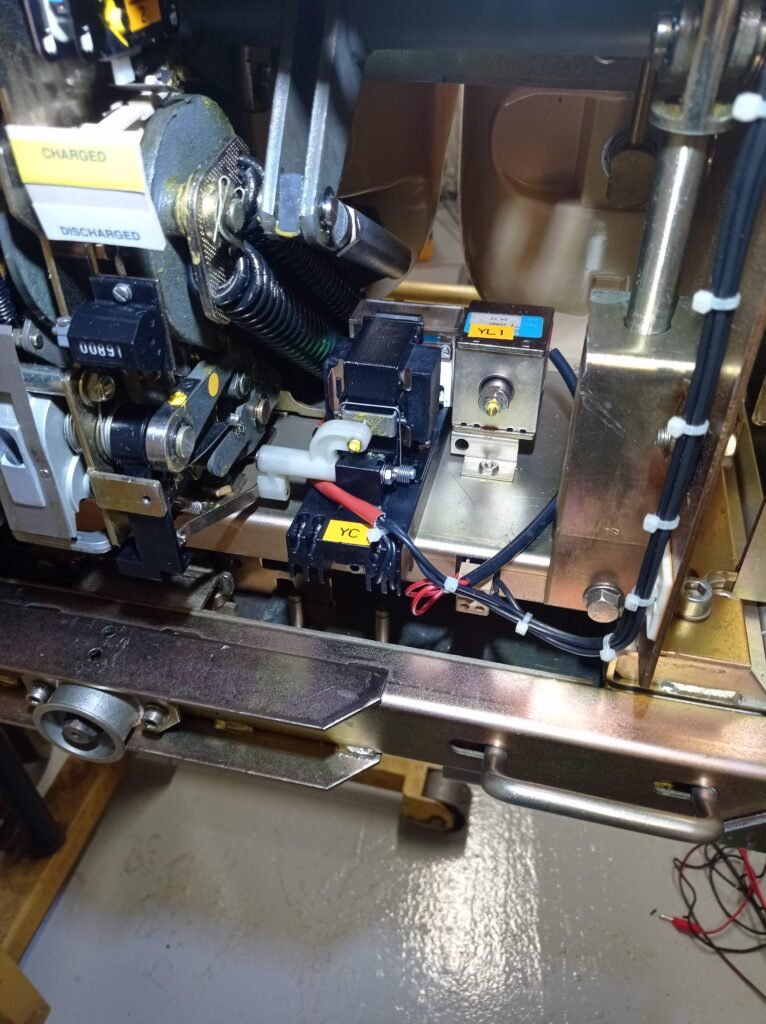

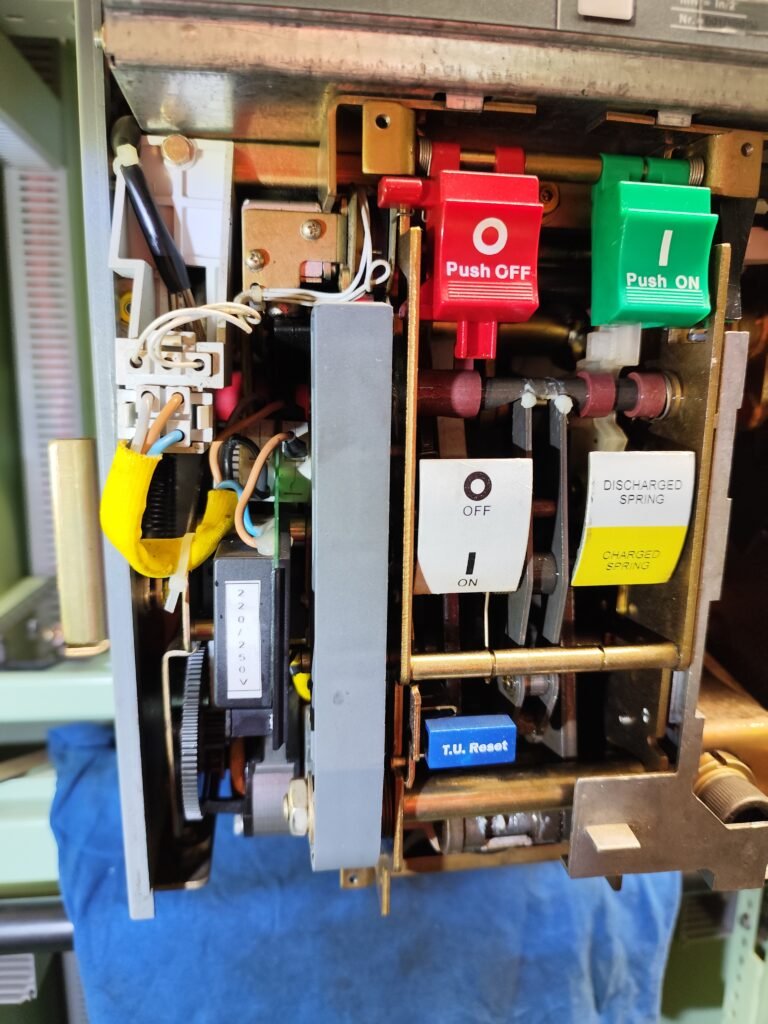

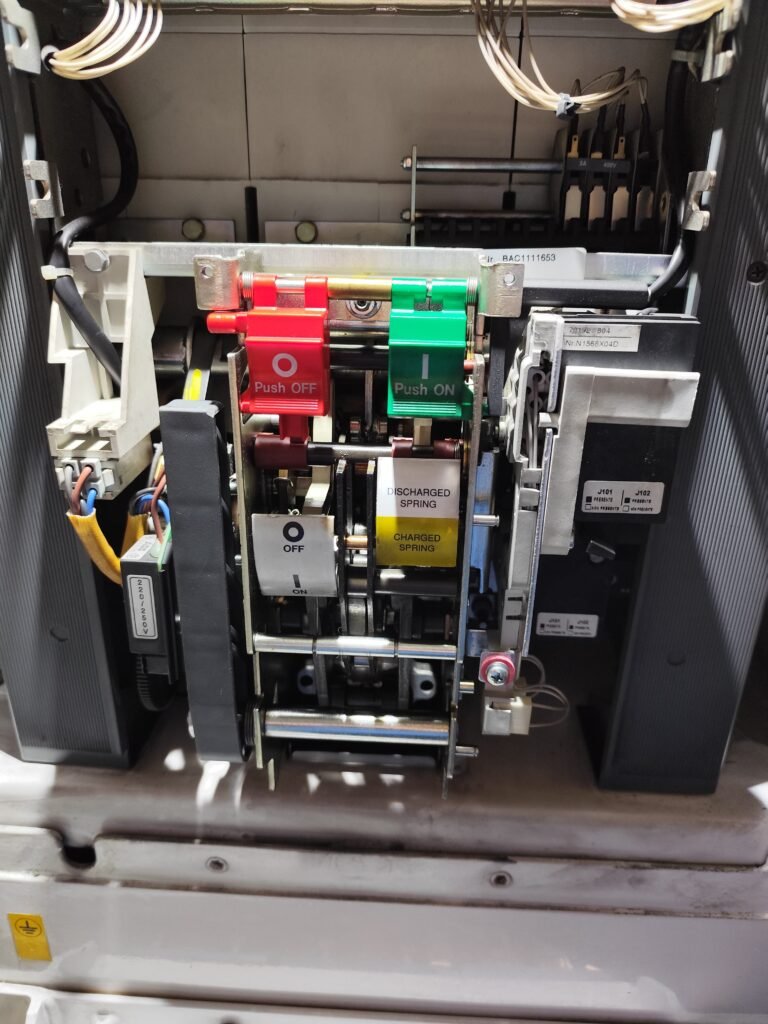

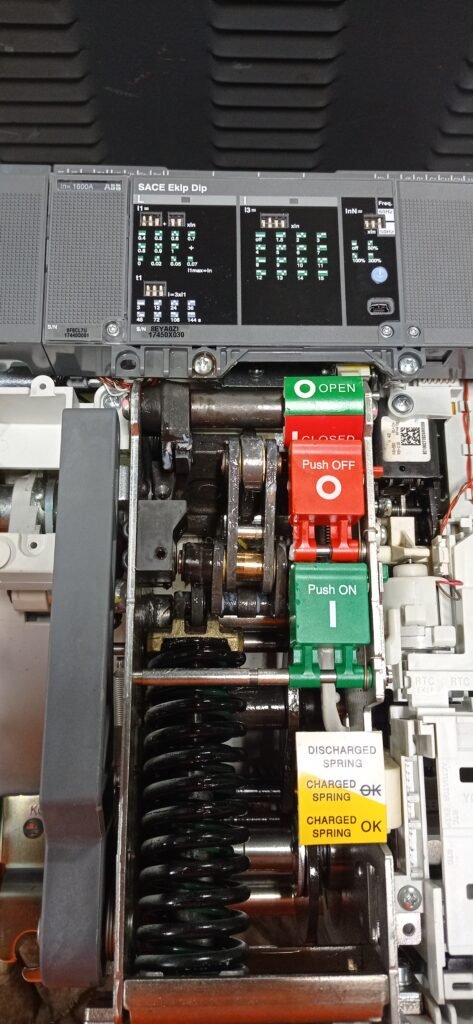

Spring Charger Motor Inspection and Test

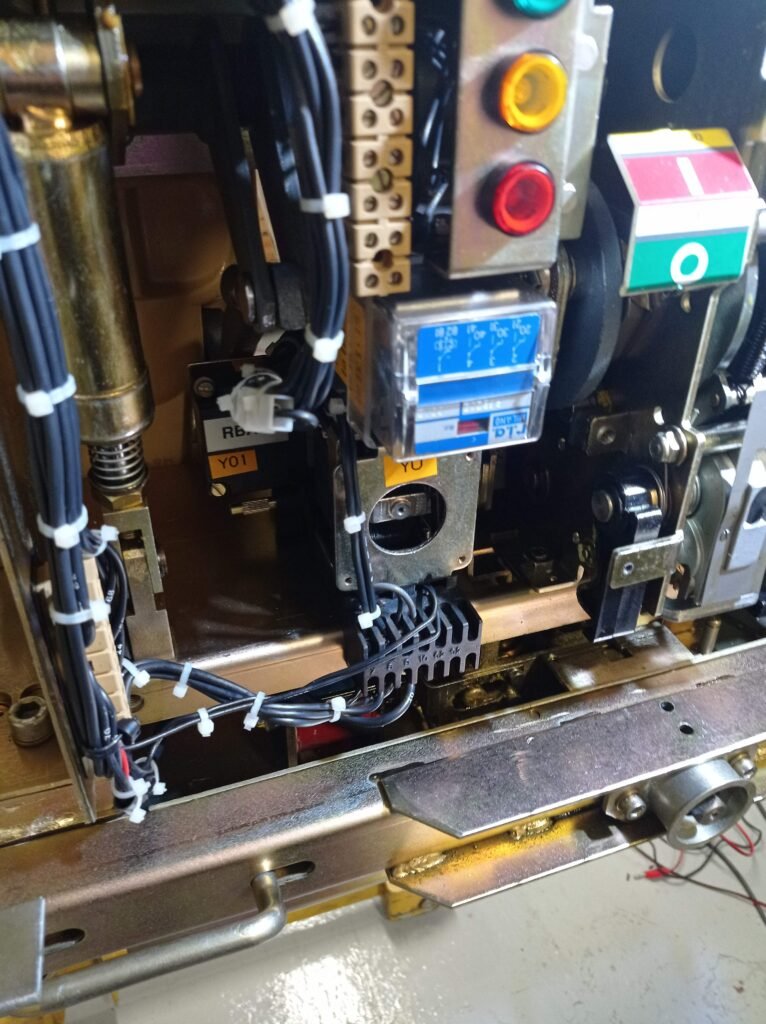

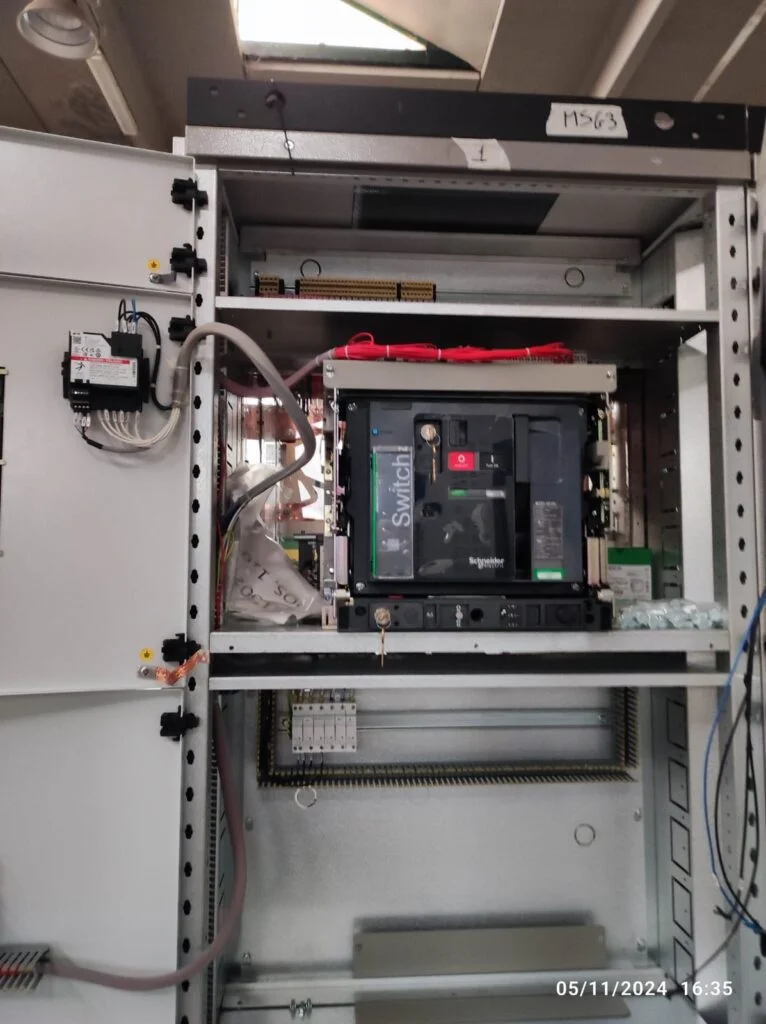

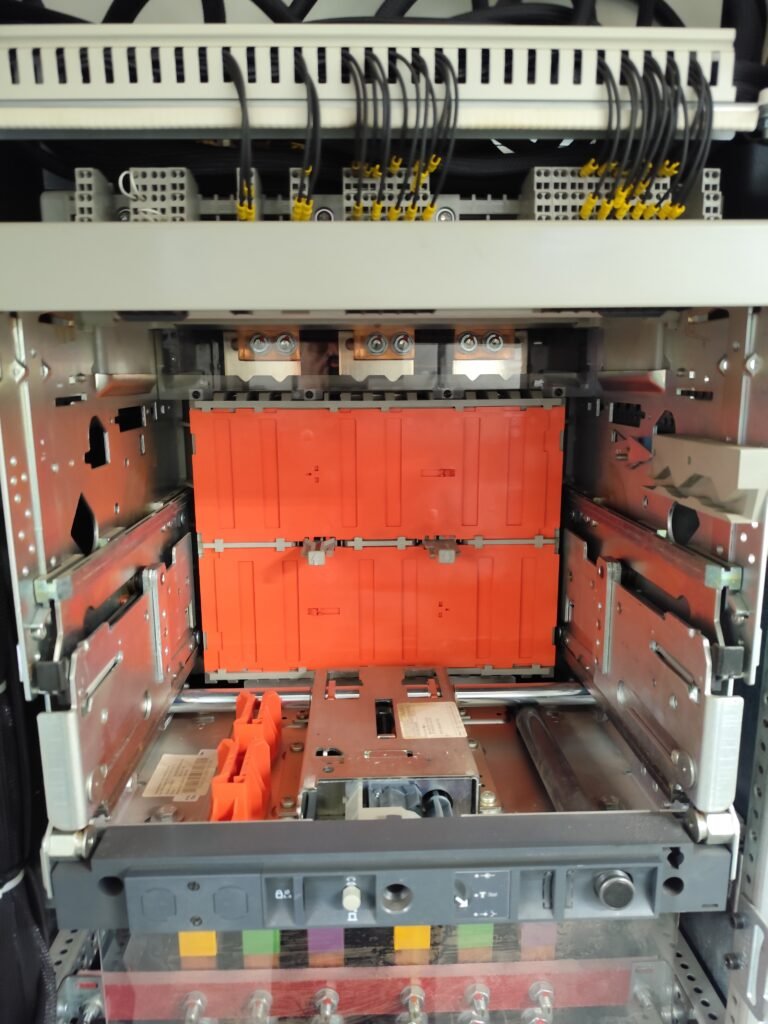

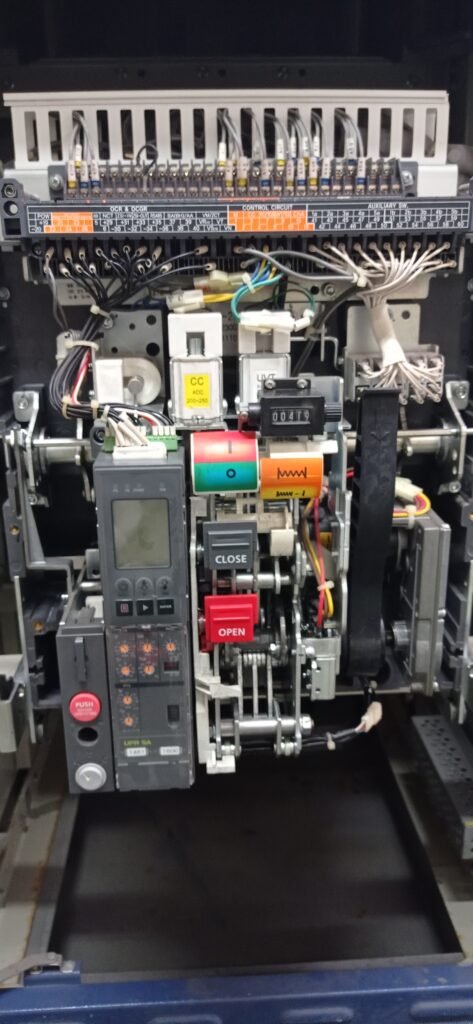

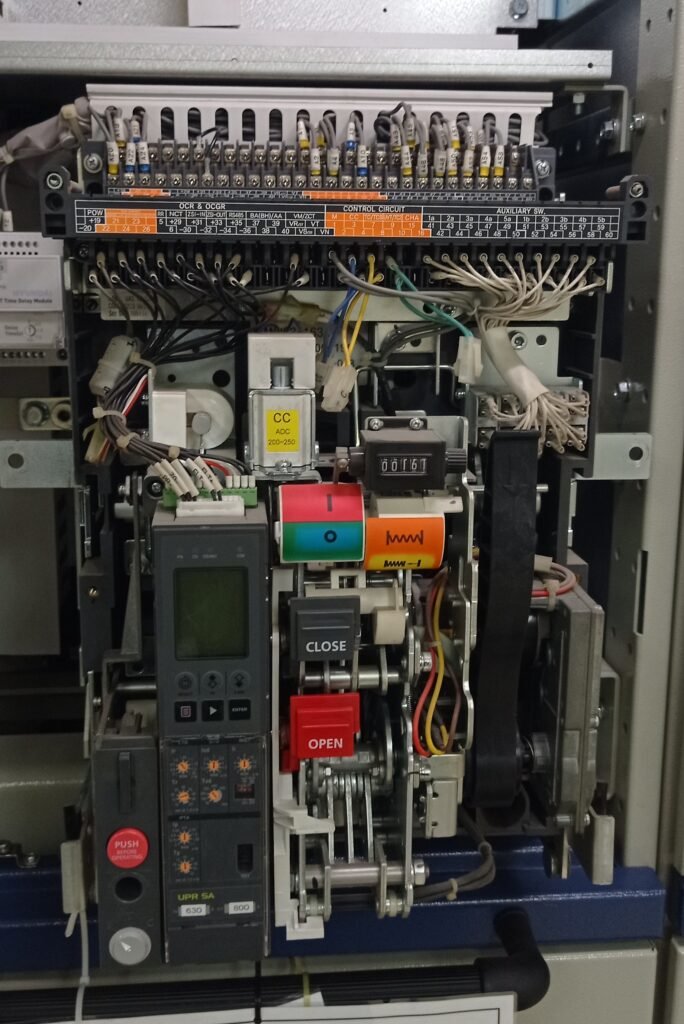

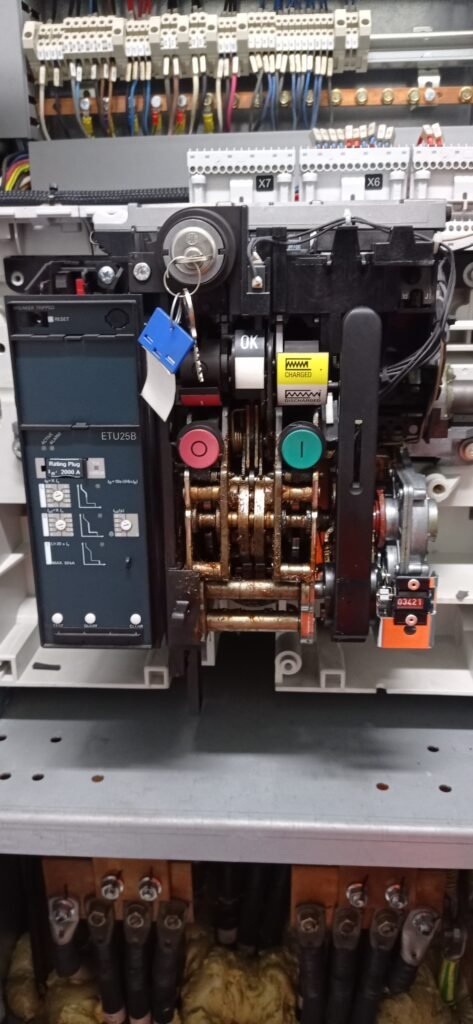

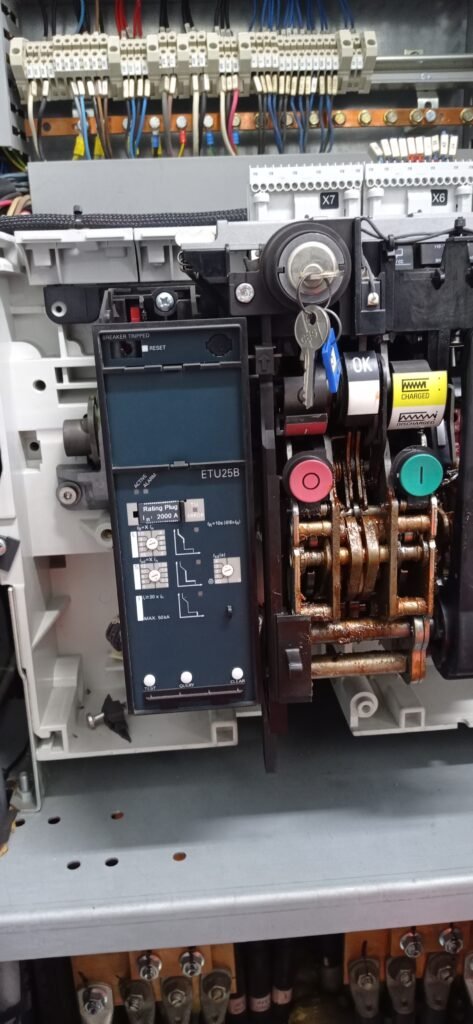

LV BREAKER SCHNEIDER NW SERIES

Breaker Inspection

Mechanical inspection

STR realy Test

Cubicle Inspection

LV Breaker

Merlin Gerin serie M

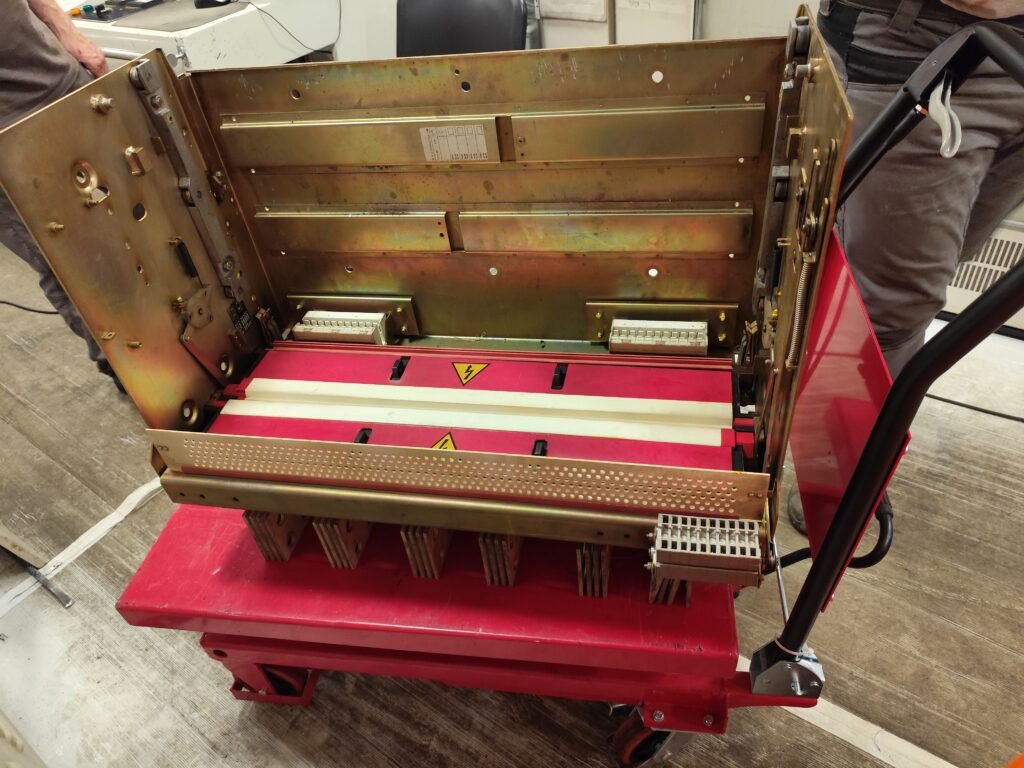

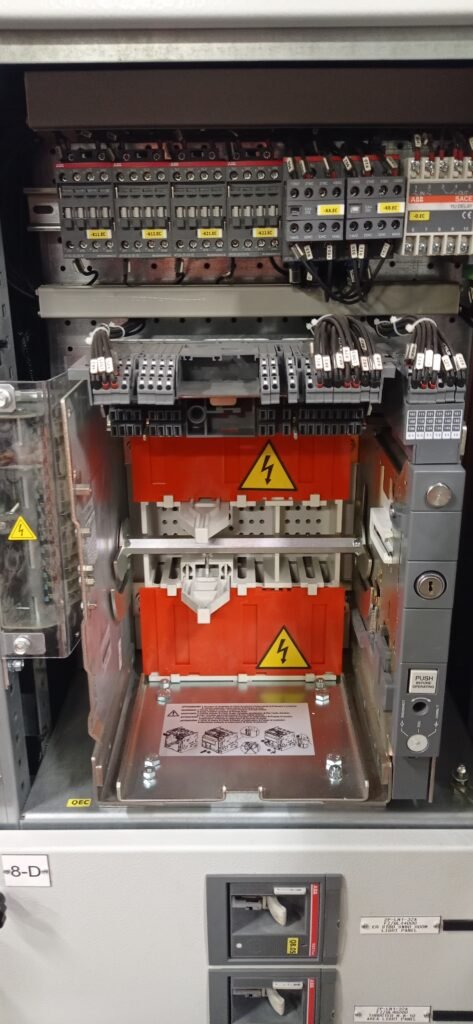

Breaker extraction

Micrologic Data Test

Coil Test, and Closed, Open Test

Inspection of the chambers

Breaker Hyunday With protection

Insulation Test

LV Breaker HYUNDAI

Inspection and cleaning breaker

Contact inspection

Breaker Cubicle

Cubicle inspection

Breaker Test

Siemens LV Breaker

LV Breaker Maintenance

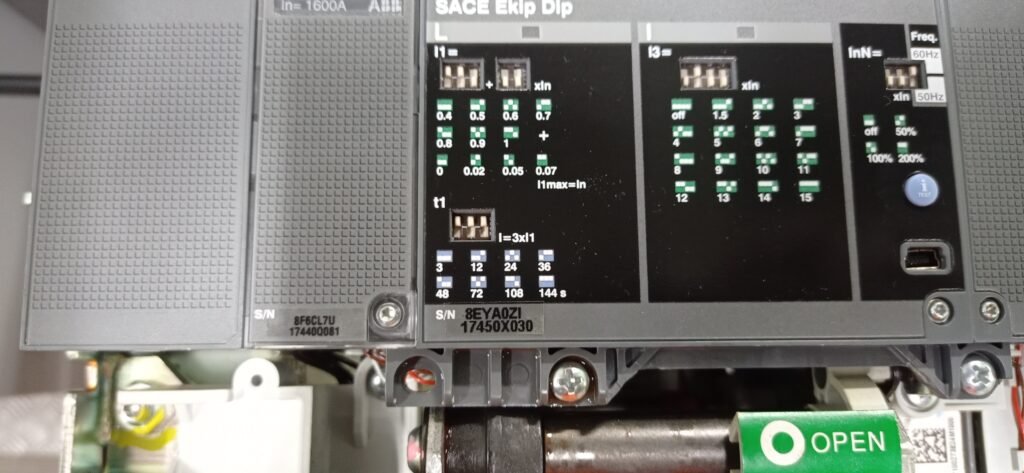

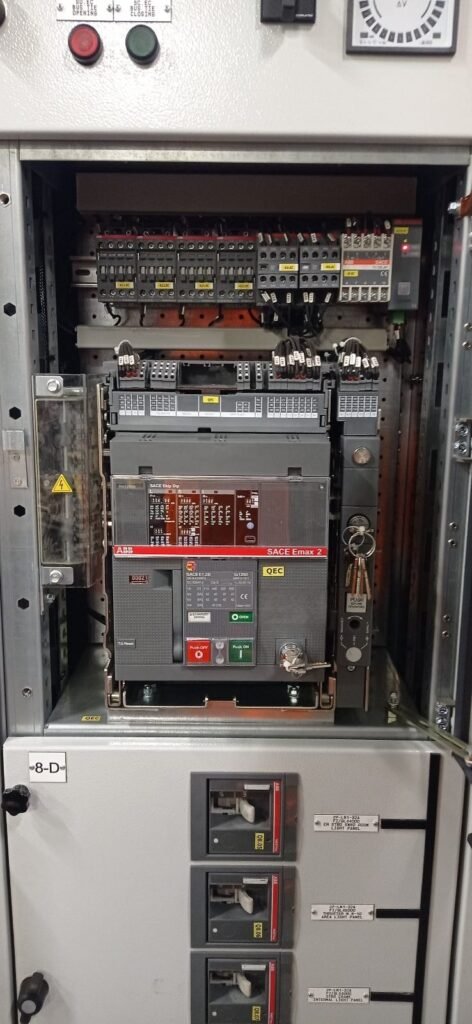

LV BREAKER ABB

Relay Test

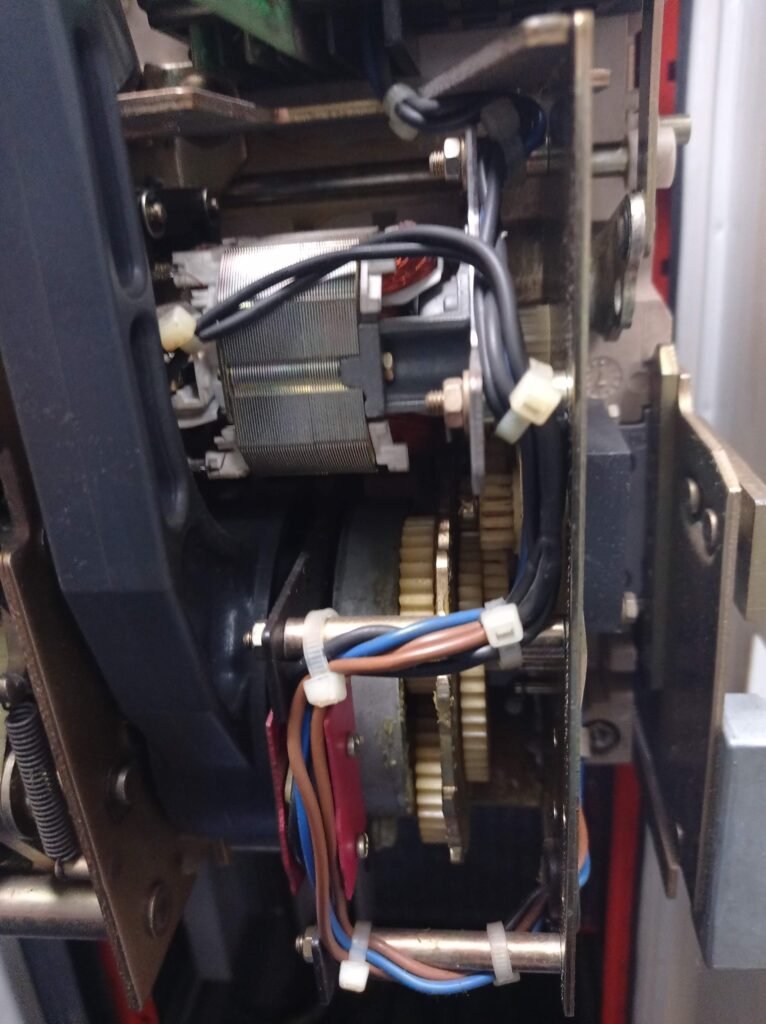

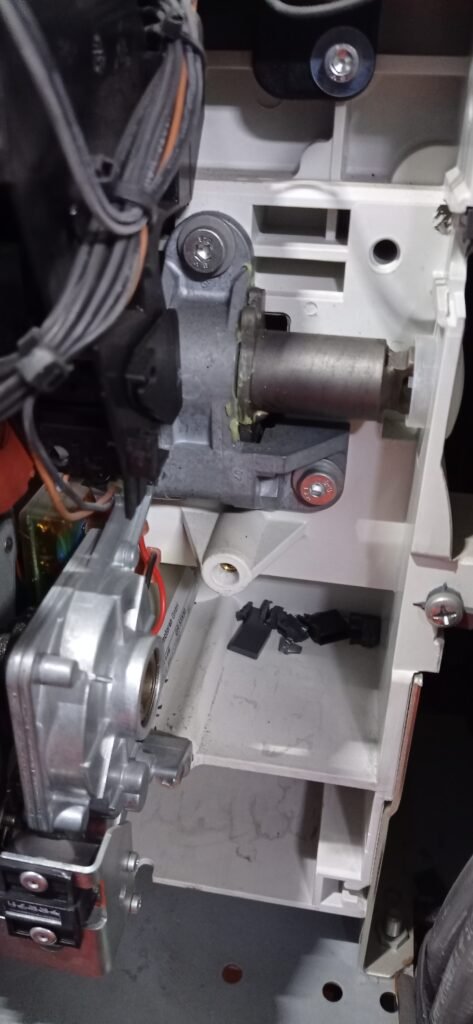

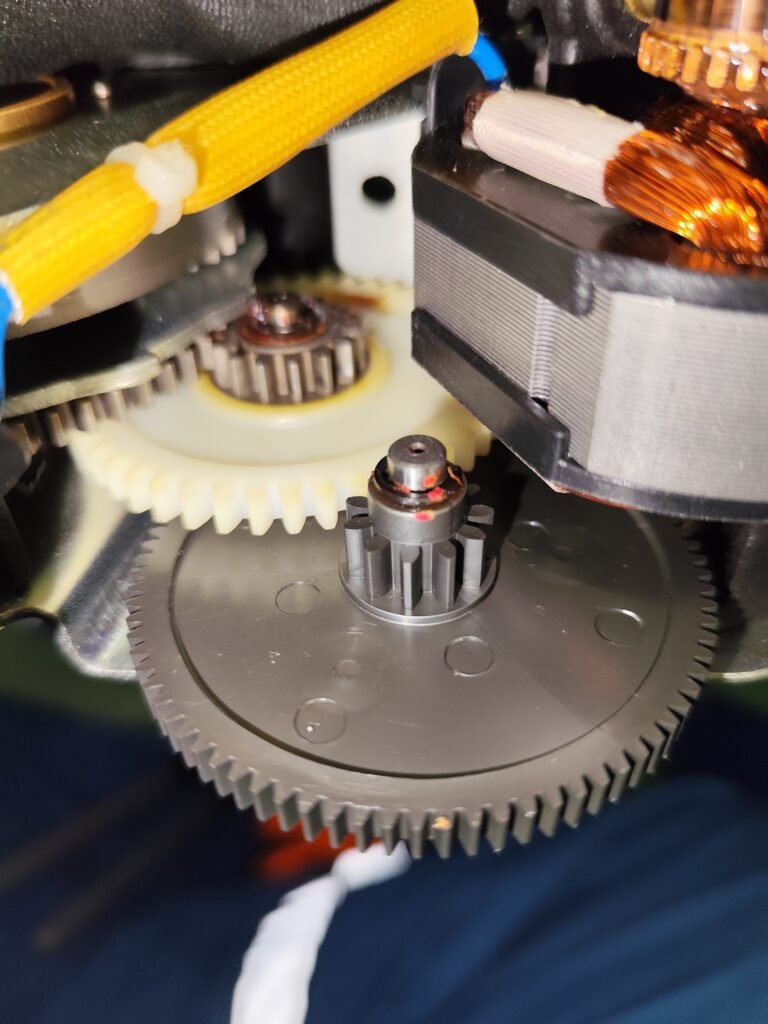

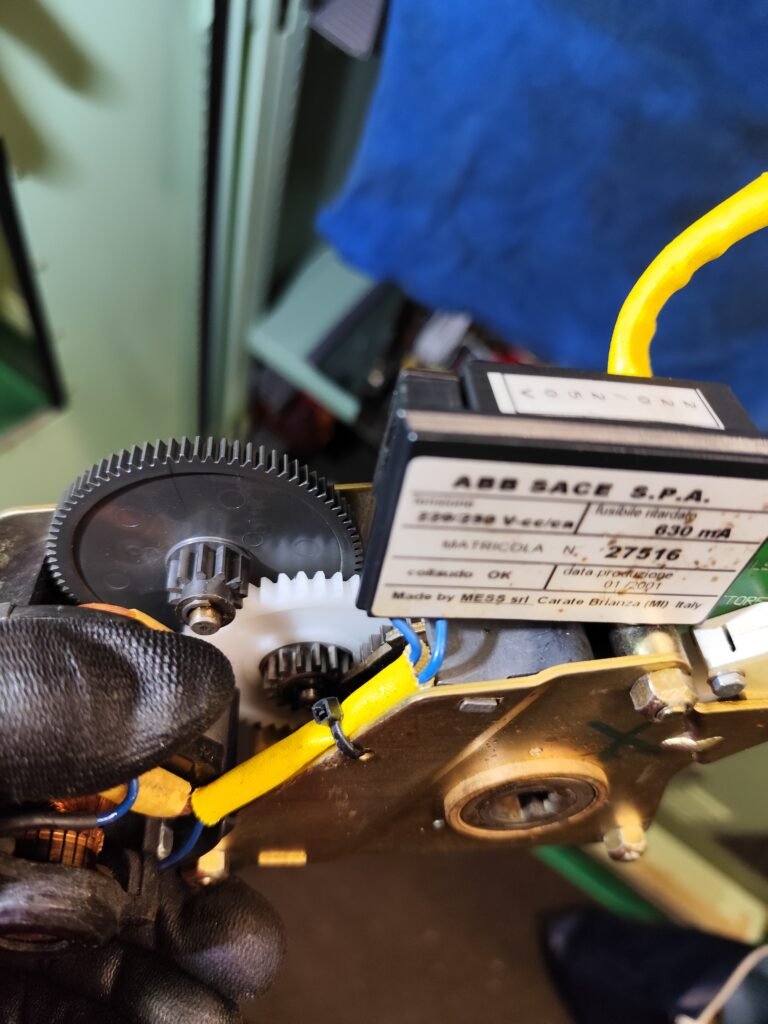

inspection of motor winding resistance value

inspections of movement mechanisms 4 contacts

inspection of motor gears

Motor cleaning and oiling

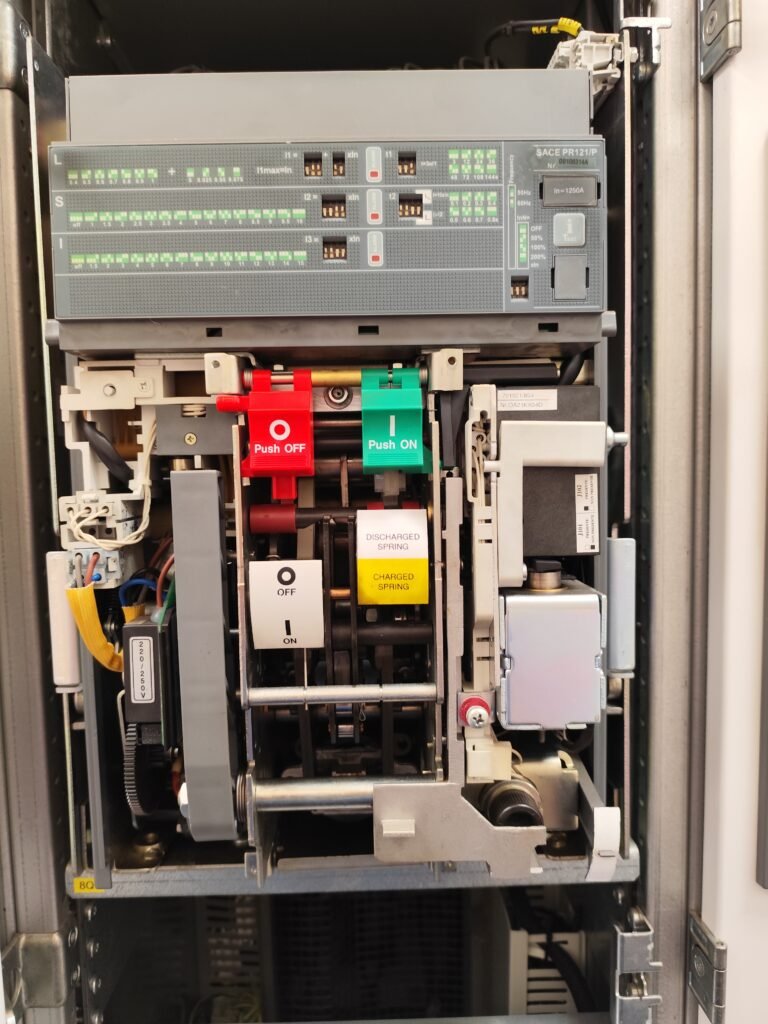

breaker Emax

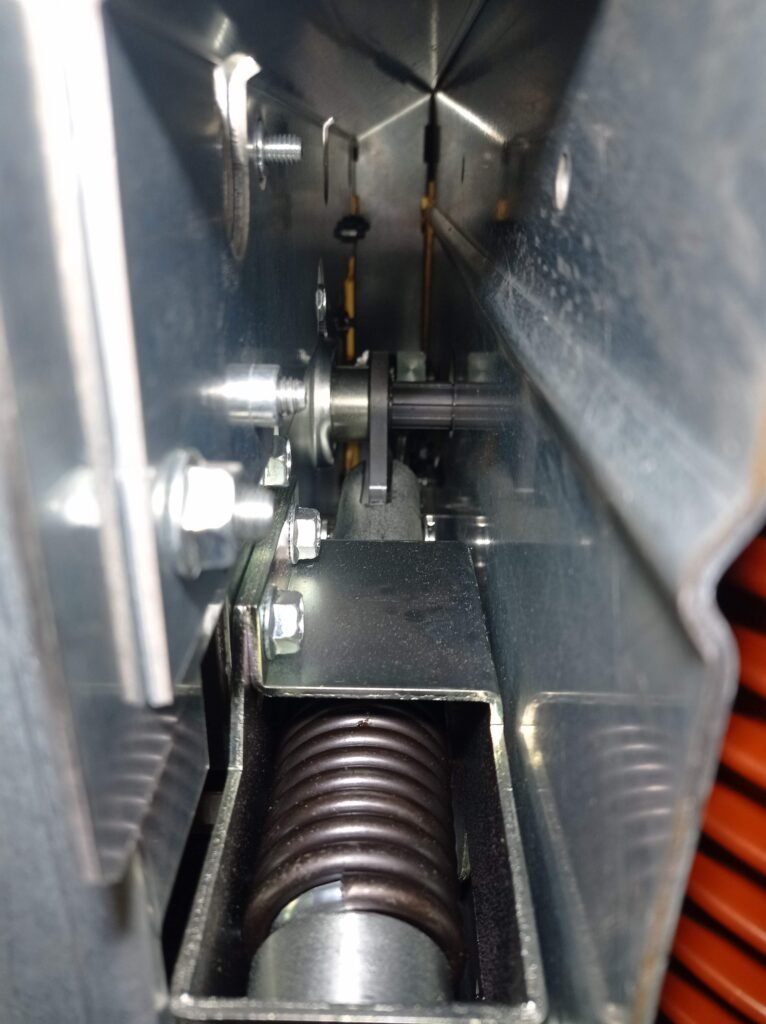

inspection, cleaning, oiling and greasing of the spring system

Inspection of the chambers

“maintained chamberes

Breaker ABB Emax

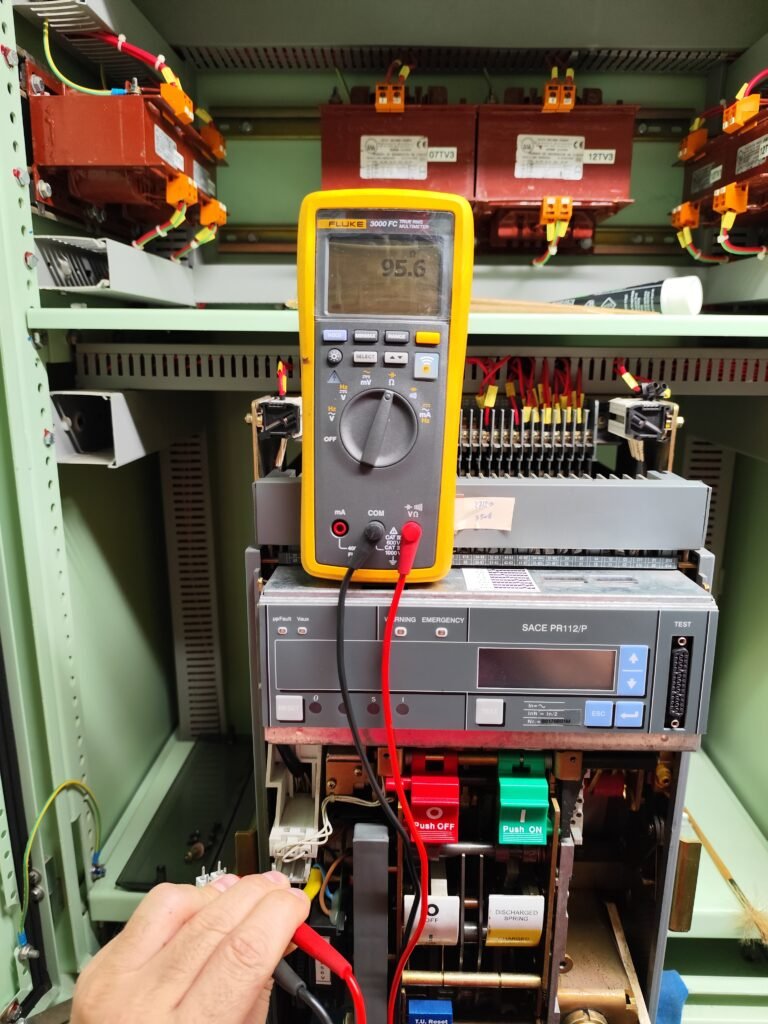

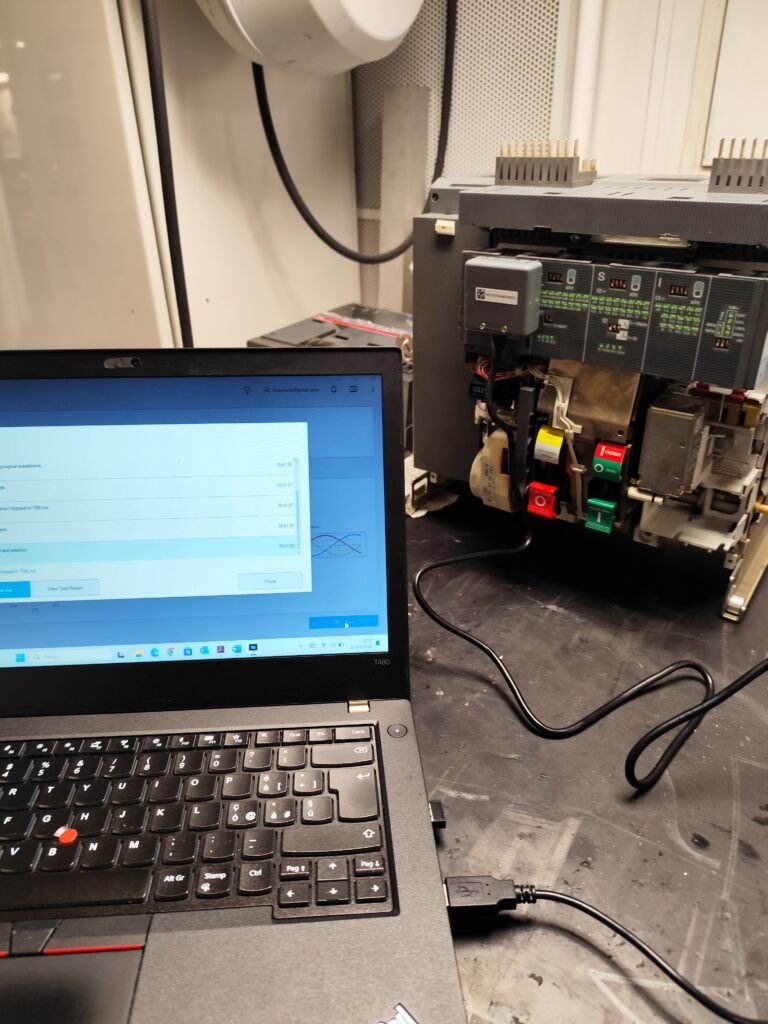

Technical instrumentation for relay testing

Insulation Test

Test Kit T&P ABB

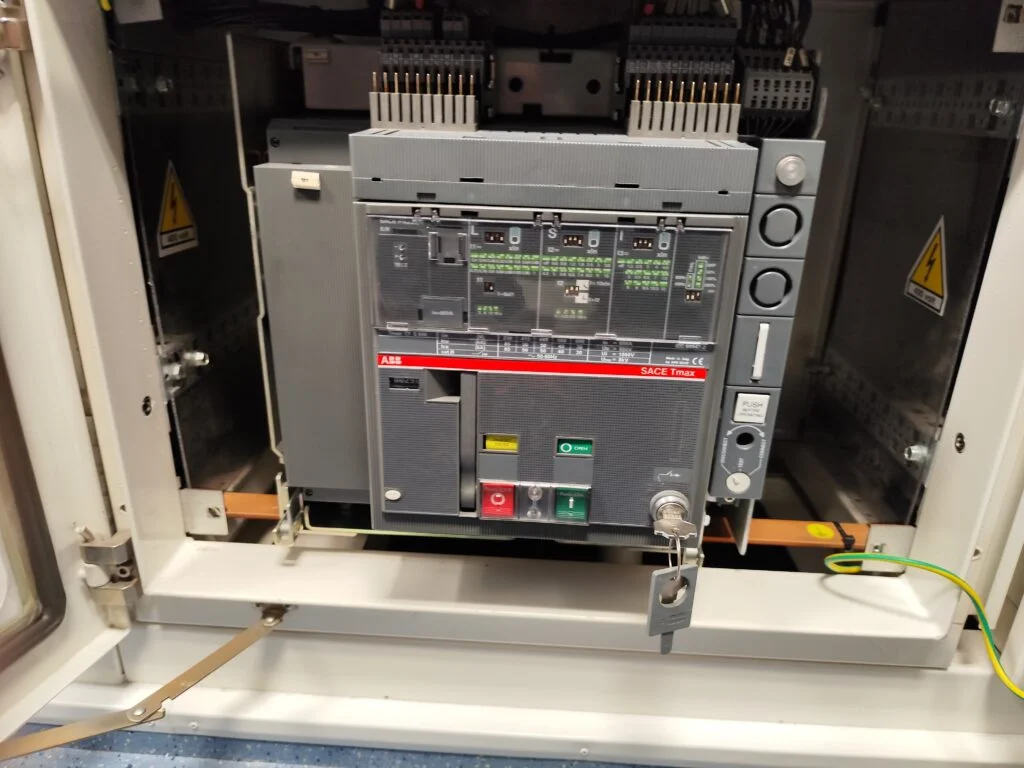

ABB Breaker TMax

Breaker with Protection relay PR121/P

Breaker ABB TMax

Cleaning of the chambers

ABB TMax nspection, cleaning, oiling and greasing of the spring system

Maintenance of ABB Emax 2 LV Breaker

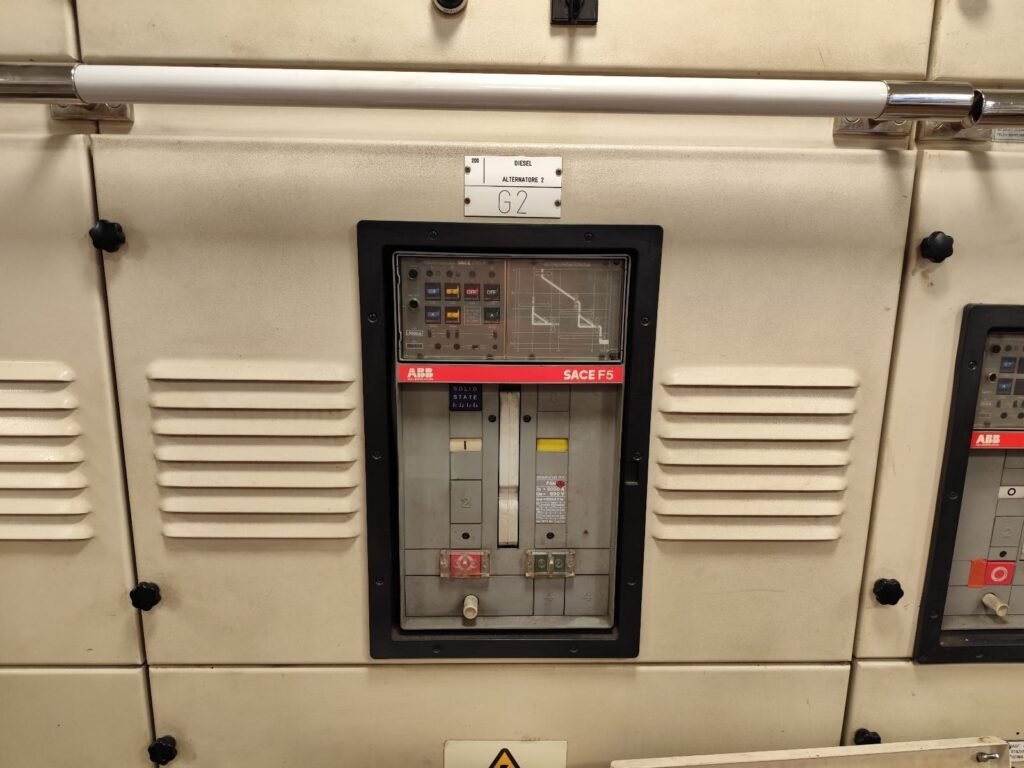

Retrofit SACE From F5 to ABB Emax 2