ABB Contactor VSC Series

CONTACTOR VCS SERIES

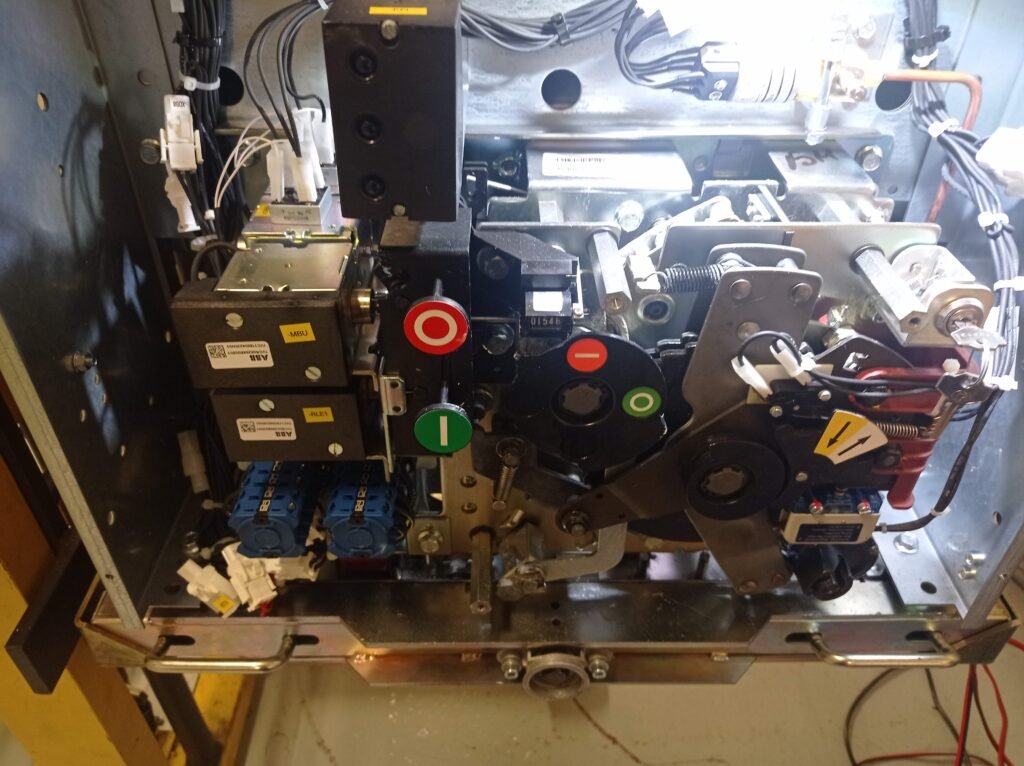

ABB VSC Contactor

The maintenance performed on this control device includes:

- Visual inspection of all moving parts, the entire structure, and electrical parts.

- Inspection of the magnetic control, including coil excitation testing.

- Inspection of the power supply system.

- Inspection of all mechanical connection points, oiling, and greasing.

- Electrical testing of the vacuum interrupters, insulation testing, and continuity testing.

- Inspection of the contactor’s truck.

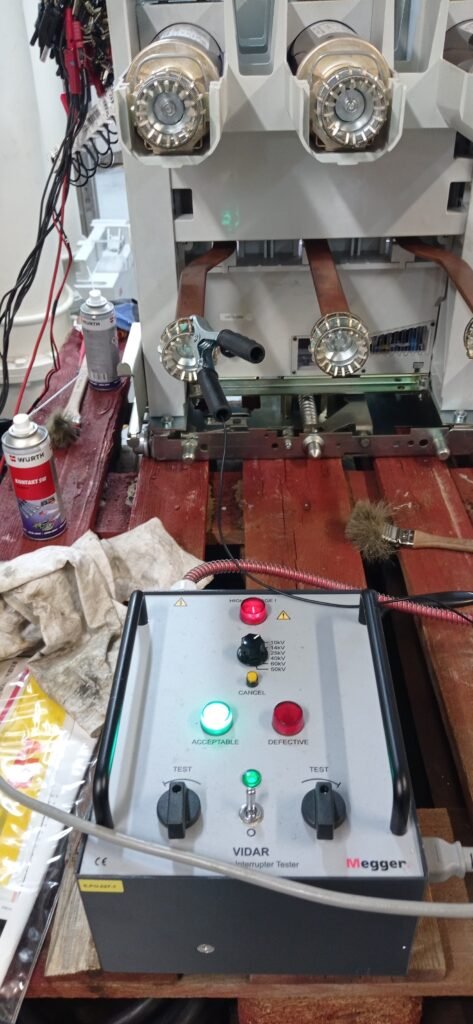

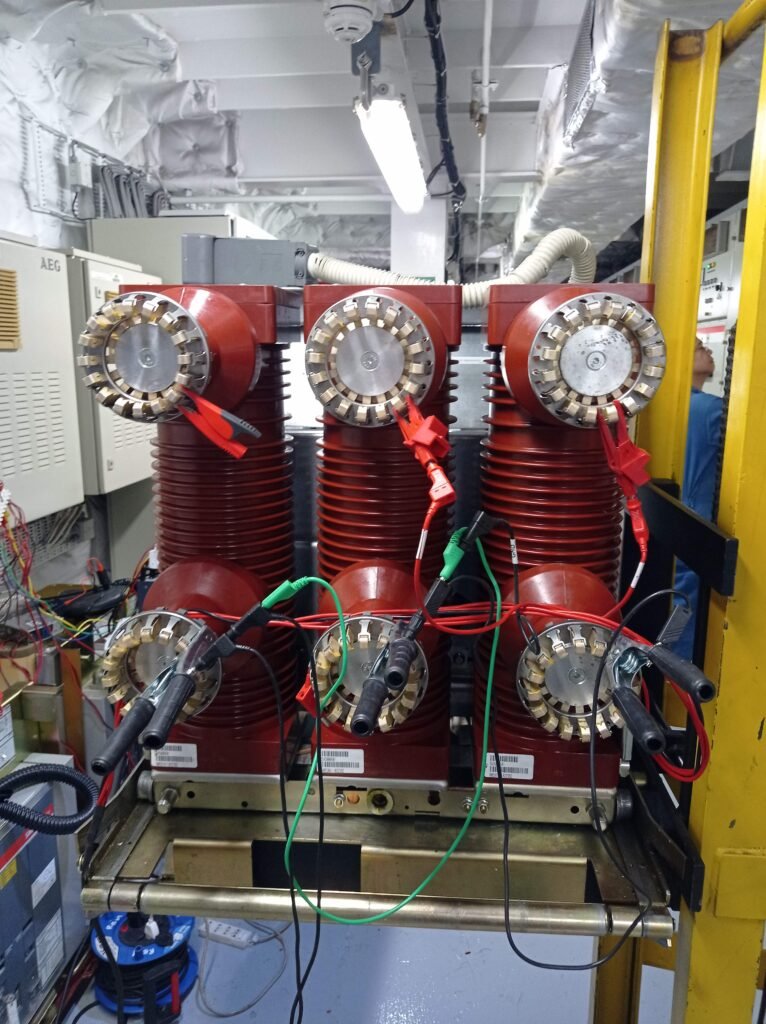

VIDAR testing of vacuum contacts

vacuum ampoule Contact

Open contact of the vacuum ampoule with evidence of the inspection measurement

Closed contact of the vacuum ampoule with evidence of the inspection measurement

ABB Breaker HD4 wìth FS6 Gas

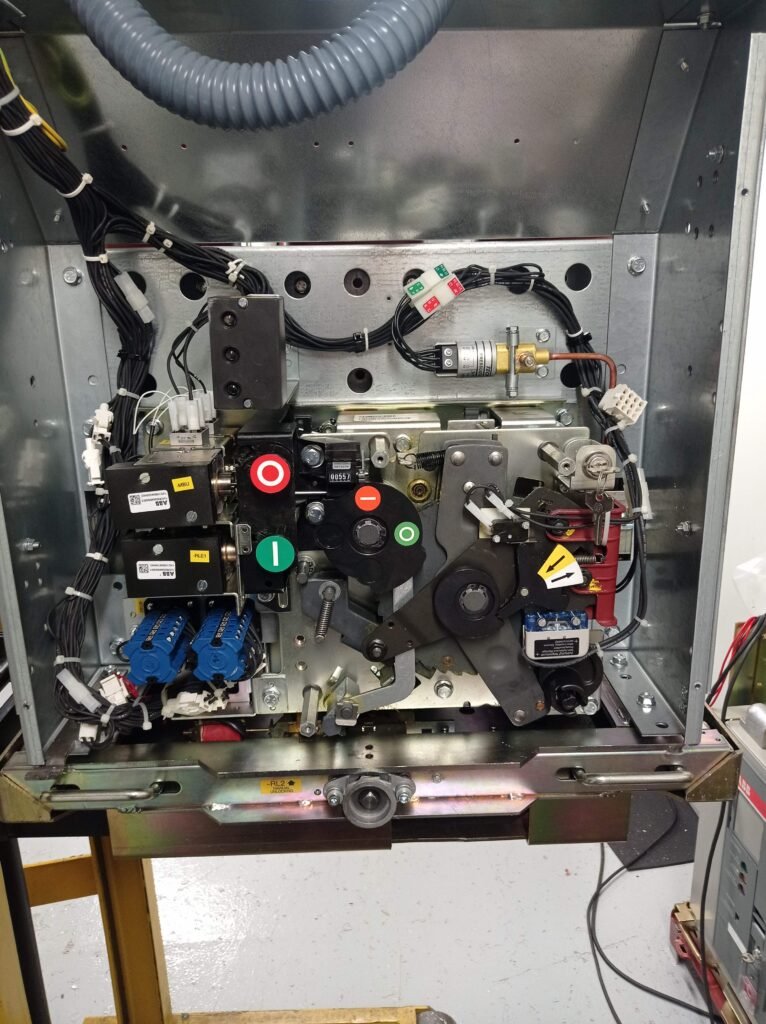

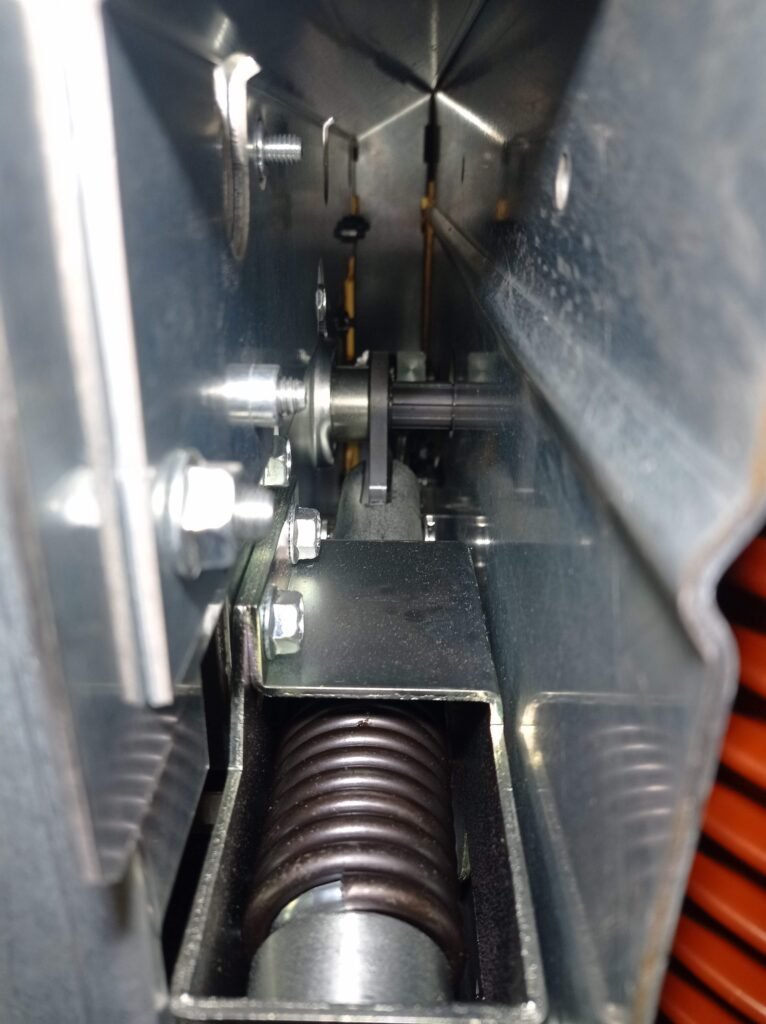

The first step is the visual inspection, then proceed with the inspection of the moving mechanical parts, cleaning, oiling, and greasing. Then we move on to the actual control of the opening and closing hammer of the mechanical spring system.

Inspection of the rotary closing system of the 3 contacts

ABB HD4 Breaker SF6

SF6 Circuit Breakers

A sulfur hexafluoride (SF6) circuit breaker uses contacts surrounded by SF6 gas to quench the arc.

They are most often used for transmission-level voltages and may be incorporated into compact gas-insulated switchgear. In cold climates, supplemental heating or de-rating of the circuit breakers may be required due to liquefaction of the SF6 gas.

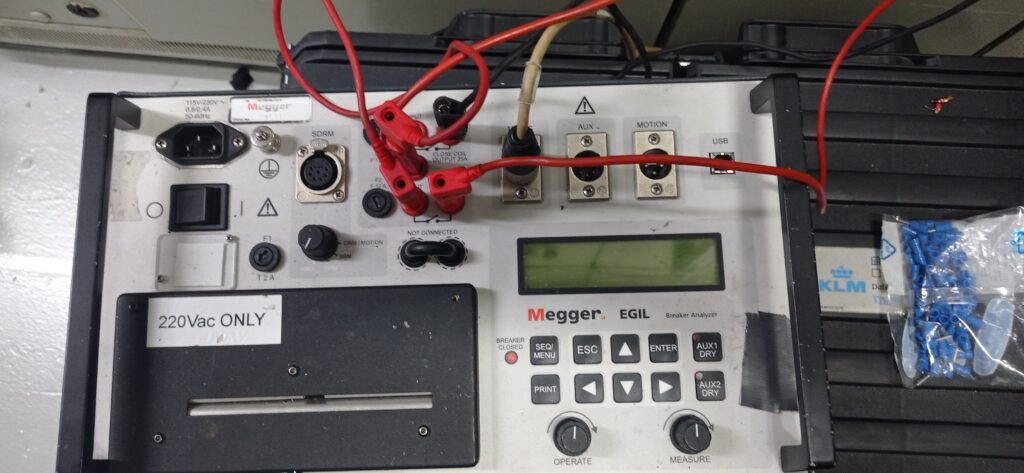

Test Instrument for the test opening and closing times

Inspection of the coil assembly, Inspection of the manual closing and opening system of the breaker Inspection of the spring charging motor, Inspection of the charged spring contact, Inspection of the moving contact group, Inspection of the SF6 gas pressure detection system.

Insulation test with contacts closed, open, and to ground

Test of opening and closing times, and phase shift in opening and closing